The LORD Electronic Materials blog has moved!

The LORD Electronic Materials blog has moved!

The current content will remain here temporarily, but make sure to visit our new site and sign up to receive new posts so you don’t miss the latest commentary and electronic material solutions.

The LORD Electronic Materials blog has moved!

The LORD Electronic Materials blog has moved!

The current content will remain here temporarily, but make sure to visit our new site and sign up to receive new posts so you don’t miss the latest commentary and electronic material solutions.

by Eric Wyman, Senior Scientist, Automotive, Industrial, and Electronics Assembly and Electronic Materials Group, LORD Corporation

Eric Wyman

Extending the life of your power electronics requires the maintenance of low thermal resistance as well as protection from shock, moisture, and debris.

Although the traditional thermal interface material solution selected for use between a heat generating device and a heat sink is a gap pad, thermally conductive gap fillers are growing in popularity as a means to fill all those nooks and crannies. Best suited for large volume applications, gap fillers can be quickly dispensed and the pattern can be modified to suit part tolerances. They are a stay-in-place solution and cure as a gel, easing the stresses caused by thermal differences and flex.

Although gap fillers have already been accepted as a solution for microelectronic applications, there is a great market need for products used in between battery modules and cooling plates in a variety of Electric Vehicle (EV) applications.

For example, gap fillers used in battery packs solve the need for effective heat transfer between cells and the cooling plate – a great option if you do not need adhesion between the two substrates. Typically more economical than gap pads, gap fillers have recently been used in large-format power electronics as a thermal interface material between switching electronics and the cooling plate. One technical advantage of gap fillers is that they can exhibit a high thixotropic index, allowing for easier and faster dispensing. Further, they offer excellent isolation and vibration dampening. Of note, though electrically isolative, gap fillers do not include an isolation film as some gap pads do, so depending on the design (bare metal) and the area (small), a gap pad may be the better choice.

In response to this market need, LORD has developed gap filler solutions specifically for large volume automotive applications. For example, LORD ThermosetTM GF-1400 thermally conductive silicone gap filler is a two-component system designed to provide excellent thermal conductivity for electronic applications, while retaining desirable properties associated with silicones. It exhibits low shrinkage and stress on components as it cures, is composed of an addition-curing polydimethyl siloxane polymer that will not depolymerize when heated in confined spaces, and provides excellent thermal shock resistance.

LORD application engineers are available to help you select the correct solution that aligns with your budget and optimize your process to improve performance. Contact us here.

Click here for a video on LORD thermal management gap filler being dispensed by Scheugenpflug equipment at IPC APEX Expo 2017 in San Diego.

The U.S. Department of Energy (DOE) installed this 1 MWh solar plus energy storage system to power Cuttyhunk Island, located off the coast of Massachusetts Photo by Stephen Coffrin, courtesy of Flicks/U.S. DOE

**This is the third post in a three-part series on energy storage systems.

by Prasanna Srinivasan, Manager, Business Development & Marketing at LORD Corporation

The momentum behind the electric vehicle (EV) market is driving significant focus on energy storage systems (ESS). With the automotive sector taking the lead in technological advancements, it has been enabling options by automating processes and driving down costs.

In particular, EVs enabled further advancement of lithium-ion (Li-ion) batteries and more widespread access to this technology. The energy storage industry has benefitted from the automotive industry, allowing it to leverage the lower battery costs for energy storage with more cost parity using an existing solution.

Cost parity is one of the key factors driving energy storage systems, especially because of its synergy with the EV market. The general consensus in the EV market is that Li-ion batteries are the preferred solution because of their superior energy density. Essentially, more power can be packed into a smaller space. Although Li-ion is the dominant technology for EVs, other technologies will continue to co-exist.

There are still many diverging battery designs and myriad different battery chemistries. EVs are using four of these five commercially established Li-ion chemistries: lithium cobalt oxide (LCO), lithium manganese oxide (LMO), lithium iron phosphate (LFP), and lithium nickel-manganese-cobalt oxide (NMC).

Battery chemistries also continue to progress. As developers and researchers in the industry argue that Li-ion batteries are reaching maturation and their theoretical limits, research continues on next-generation technologies such as lithium-sulfur (Li-S).

Purdue University researchers are also working on an “instantly rechargeable” battery that could be a game changer for the future of electric and hybrid vehicles. This technology would enable drivers to fill up their electric or hybrid vehicles with fluid electrolytes to re-energize spent battery fluids similar to refueling a gas tank.

Prasanna Srinivasan

Instead of refining petroleum into gas, spent electrolytes would be reprocessed and fueling stations would dispense a water and ethanol or methanol solution as fluid electrolytes to power vehicles.

The researchers say that the battery fluids or electrolytes that have been expanded, could be collected and taken to a solar farm, wind turbine installation or hydroelectric plant to be recharged. This would be a significant development for the energy storage market, particularly in terms of infrastructure. It could be essentially likened to a “plug-and-play” type solution.

As electric and hybrid vehicle sales continue to gain popularity, advancing energy storage solutions is essential. Looking at energy storage in monetary terms, the market is expected to grow 8 percent a year to $50 billion in 2020. Any gains on the EV side can carry over into other facets of energy storage. Also, research is underway to repurpose EV batteries for ESS.

However, demands for stationary energy storage are different from the EV market. Space and weight are less of a constant than in EV. This, in turn, translates into thermal management, where the requirements and demands are very different. As batteries increase in energy density and the need to achieve cost parity with the grid continues to exist, innovations in thermal management will continue to be developed.

The energy storage market both within the EV sector and outside of it is rapidly growing and creating numerous opportunities. Repurposing EV batteries that have lost the capacity for solar energy creates new opportunities to give these batteries a “second life.”

Although the battery may no longer be suitable for use in an EV, it might be sufficient for energy storage. As the number of EVs on the road continue to increase, the sheer volume of batteries used for them can drive down costs. It also means there will be an increased need for places to charge the batteries, presenting an even greater opportunity for the batteries’ reuse to store solar power. It also extends the overall life of the battery, reduces costs for stationary storage, and it delays recycling.

This is an exciting time as companies develop new technologies and next-generation solutions in efforts to optimize solutions and decrease costs. It’s also the time to get involved in the design process – to collaborate and be part of developing solutions.

At LORD, we continue to advance our thermal management solutions, which complement energy storage solutions. We already know that proper application of thermally conductive materials will improve motor power density (for a white paper on this topic, click here), but there is so much more to be developed and discovered.

What ideas do you have for the next generation of energy storage solutions overall and within the EV market? What thermal management solutions do you think will be needed to further advance energy storage? What do you think the future holds for energy storage? Let us know here.

For more on energy storage, see the other posts in this series:

by Prasanna Srinivasan, Manager, Business Development & Marketing at LORD Corporation

It’s no secret that the U.S. electrical grid system is overtaxed and outdated, and integrating methods to decrease dependence on it is critical. Modernizing the system will help position the country to meet future projected energy needs and reduce the electric load. By some estimates, the U.S. will need somewhere between 4 and 5 terawatt-hours of electricity annually by 2050.

There have been tremendous breakthroughs and continued growth in the energy storage market, which can play a significant role in expanding the grid to handle an increased load and improve operating capabilities.

Energy storage systems (ESS) can also support emergency preparedness efforts, reduce the need for major new transmission grid construction upgrades and augment the performance of existing transmission and distribution assets.

The U.S. Department of Energy (DOE) recognizes that by reducing peak loading (and overloading) of transmission and distribution lines, storage can extend the life of existing infrastructure.

Despite all these factors in favor of energy storage, several challenges remain, including:

Multiple technologies: There are multiple energy storage technologies – chemical and non-chemical categories of storage – and a lack of convergence with lithium-ion (Li-ion), flow batteries and non-battery solutions such as mechanical or thermal storage.

System costs: Overall system costs also must be considered because a single solution may not be applicable across the board. Instead, a different approach may be needed for various regions and system architectures to make energy storage economically feasible. Energy storage system technologies need to be cost competitive, but they are still in the early stages. Costs will come down as companies begin optimizing these ESS technologies. This includes the price for Li-on batteries, which currently dominate the market. This elevated demand is driving production and affecting the price.

However, costs are coming down, particularly in light of the progress that has been made in terms of electric vehicles. As large-scale batteries reach economies of scale, the cost reduction will also translate to energy storage.

Safety concerns: Various safety concerns, such as how batteries of different chemistries and technologies react in a fire, exposure to toxic fumes, how responders handle a damaged battery that still contains energy and hazards associated with energy storage systems, among other safety issues, present their own set of challenges.

Regulatory barriers: Institutional and policy barriers pose challenges with energy storage. What rules and regulations will be put in place? How storage systems in various markets will be regulated and what cost-based and market-based, cost-recovery for owned or contracted energy storage assets need to be determined. California may lead the way. In mid-February, the California Senate introduced a bill that would require the state to make 100 percent of its energy from renewable sources by 2045.

Thermal Storage Tanks were installed as part of an energy conservation construction project for Naval Submarine Base Kings Bay. Source: Flickr

Currently, guidelines are being drafted in Australia that may ban lithium-ion battery storage devices from being installed inside homes and garages, allowing them only in in free-standing “bunkers.”

This would not only affect everyday consumers, one of whom is Australia’s prime minister, but it also could also affect large-scale installations. If the ban is implemented, it could pose issues for people who have electric vehicles, which are powered by Li-on batteries.

However, Elon Musk, Tesla Motors CEO and chairman and founder/CEO of SpaceX has been in the news for boldly suggesting to the Australian government that he could solve a looming energy crisis in South Australia – which has experienced blackouts the past few months – through ESS. Musk said that he could install a battery system within 100 days or it would be free.

Strategy in approach: Strategic issues challenge energy storage. How do you develop a systemic or a holistic approach to senergy torage that addresses and bridges technical regulatory and market and political aspects? Determining a strategy incorporating these various silos is important. Developing a pricing model around vehicle-to-grid (V2G) – using batteries in electric cars as grid storage devices – and other related challenges must also be strategically addressed, especially because V2G storage requires such an extensive infrastructure.

Idaho National Laboratory (INL) Energy Systems Laboratory is the research and development technical leader for developing bio-energy feedstock supply systems, important to renewable energy portfolios. In July 2013, the Department of Energy designated INL’s biomass feedstock research effort as a national user facility. Source: Flickr

Consumer acceptance: The idea of energy storage may be attractive and exciting, but here are some unknowns. For true acceptance and adoption of ESS, consumers need to understand the how and why of energy storage and be able to validate the safety, reliability, and performance of these systems.

Even with these limitations and challenges, the energy storage market is ultimately situated to grow very rapidly. Learn about it and plan for it, but expect the automotive market to actively take the lead in resolving many of the issues and challenges with energy system storage technology.

Let LORD know how you are planning for the rise in energy storage and your thoughts on the market.

Click here for “Energy Storage, Part One: Are energy storage systems the next big thing?”

Energy Storage at a Glance

To get a picture of how energy is being consumed through the United States and more about the energy storage market, check out the interactive U.S. Energy Mapping System and the 2017 Energy Outlook from the U.S. Energy Information Administration (EIA).

by Prasanna Srinivasan, Manager, Business Development & Marketing at LORD Corporation

Prasanna Srinivasan

Energy storage is not a new concept. It has been around for decades and is touted as an important tool for facility managers to optimize their facility energy system, a solution to fixing the aging power grid and increasing the spread of renewable energy. It has been a valuable tool for reducing electric bills and helps during emergencies such as power outages from storms, equipment failures or accidents.

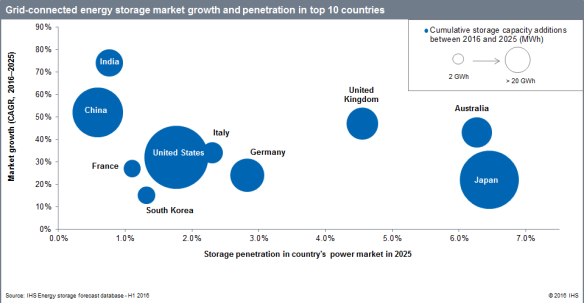

The energy storage market is positioned to “explode” to an annual installation size of 6 gigawatts (GW) in 2017 and more than 40 GW by 2022 from an initial base of 0.34 GW installed in 2012 and 2013. Analyzing energy storage from a monetary standpoint, it is expected to grow 8 percent a year to $50 billion in 2020.

The federal government has also committed to increasing energy storage and microgrid capacity, further promoting expansion of this market. In June 2016, the White House announced a series of federal and private-sector actions to scale energy storage in the U.S. at the Summit on Scaling Renewable Energy and Storage with Smart Markets.

These factors, among others, are contributing to this rapid market expansion.

Energy storage systems are expected to grow to an annual size of 6 gigawatts this year and to more than 40 gigawatts by 2022. Source: Flickr

The progress of Lithium-ion (Li-ion) battery technology. Li-ion batteries have ramped up in terms of energy and power density. Throughout the next decade, Li-ion batteries are expected to become the mainstream energy-storage technology, and more than 80 percent of global energy storage installations will include the technology by 2025.

Although the energy storage market is rapidly expanding and provides numerous opportunities, there are still kinks that must be worked out before it can be fully adopted on a mainstream level.

Although the energy storage market is rapidly expanding and provides numerous opportunities, there are still kinks that must be worked out before it can be fully adopted on a mainstream level.

For more on challenges and limitations facing the energy storage market, look for an “Energy Storage: Part 2” follow-up to this blog post. In the meantime, let us know your thoughts on the future of energy storage.

To get a picture of how energy is being consumed through the United States and more about the energy storage market, check out this interactive “U.S. Energy Mapping System” and the 2017 Energy Outlook from the U.S. Energy Information Administration (EIA).

By Eric Wyman, Sr. Scientist, LORD Corporation

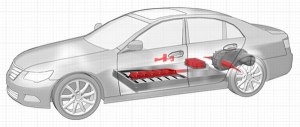

Although electric vehicles have been a possibility for almost a century, they haven’t been terribly realistic up until this point because of myriad factors including cost, design and perception. However, with pressure to reduce vehicle carbon emissions and improve air quality, Congress recently commissioned a study by the National Academy of Sciences on hurdles to adopting plug-in electric vehicles (PEVs), as highlighted in Why Don’t We Drive More Electric Vehicles?

Building on our expertise with thermally-conductive materials as well as structural adhesives, LORD has sought a means to help advance this industry and find a better solution. Applying the same expertise and experimenting with the chemistries used for materials used in the aerospace, industrial, oil and gas as well as a wide range of other industries, LORD set out to find a material that serves as both a mechanical bonding solution as well as thermal interface.According to the report, the array of options can be bewildering, ranging from long-range battery options such as the Tesla Model S, short-range models like Nissan Leaf, the range-extended plug-in hybrid model Chevrolet Volt (which drives on electric power most of the time), and minimal plug-in models such as the BMW i8 (which can perform short trips on battery power alone). Despite the growing list of options, one common theme is the need to find an efficient means to reduce the cost and improve the design of the battery pack.

Building on our expertise with thermally-conductive materials as well as structural adhesives, LORD has sought a means to help advance this industry and find a better solution. Applying the same expertise and experimenting with the chemistries used for materials used in the aerospace, industrial, oil and gas as well as a wide range of other industries, LORD set out to find a material that serves as both a mechanical bonding solution as well as thermal interface.According to the report, the array of options can be bewildering, ranging from long-range battery options such as the Tesla Model S, short-range models like Nissan Leaf, the range-extended plug-in hybrid model Chevrolet Volt (which drives on electric power most of the time), and minimal plug-in models such as the BMW i8 (which can perform short trips on battery power alone). Despite the growing list of options, one common theme is the need to find an efficient means to reduce the cost and improve the design of the battery pack.

The intent was to create a material that would eliminate or reduce the current trend of large mechanical structures, while serving as a cooling medium. By simplifying the design, we can help increase the energy density of the battery pack, which also allows for novel pack design.

One such solution is the recent launch of LORD Thermoset TC-1001, a thermally conductive, 10:1 mix ratio, acrylic structural adhesive. With a broad range of applications for bonding lithium ion cells to cooling plates, this product is similar to other LORD acrylics, yet it has higher thermal conductivity with comparable properties. Different than other commercially-available thermally conductive materials that require high cure temperatures, TC-1001 cures at room temperature with good thermal conductivity.

This product is yet another evolution and builds on the success of Thermoset SC-320 — a two-component system designed to retain desirable properties associated with silicones. Specially designed for thermal conductivity for electrical/electronic encapsulating applications, it exhibits low shrinkage and stress on components as it cures, and maintains a low viscosity for ease of component encapsulation compared to other highly thermal conductive materials.

Environmentally resistant and UL-rated to UL94V0 and 180C RTI, Thermoset SC-320 is composed of an addition-curing polydimethyl siloxane polymer that will not depolymerize when heated in confined spaces. Possible applications for SC-320 include those in which higher power at lighter weight is needed, such as motors for electric vehicles; aerospace actuators and motors; and portable power generation equipment.

As the trend towards battery-powered transportation continues, a question we ask ourselves as many others are jumping on the bandwagon is, “What is next?” Can we assume Tesla has the “car for the masses” or is a “secret” start up somewhere or are one of the big high-tech companies such as Google or Apple about to change the landscape further by launching something unimaginable?

by Jim Greig, Global Sales and Marketing Manager Electronic Materials, LORD Corporation

What is the one commodity in the world that we cannot live without? It’s not gasoline or raw materials or sugar or anything else that is traded on the commodities market. It’s water!

Up to 60 percent of the human adult body is made of water. Every day humans must consume a certain amount of water to survive; animals and livestock need water, too.

Most of us take water for granted. When I turn on the faucet, I expect clean, cold (or hot) water to flow – for drinking, washing or cooking. But this is not the case for many parts of the world where access to drinkable water and sanitation is constrained. The figures are startling – 660 million people worldwide lack access to safe water; 2.4 billion people worldwide lack access to a toilet. When humans lack access to clean water and proper sanitation, it affects their health, their livelihood, and their ability to function as part of the global community.

So how do we maintain a water supply that is clean enough to drink and clean enough for the human race to survive? If the world does not have enough drinkable water – we’re “toast.” (Or think of it this way – what if you didn’t have a clean source of water to make coffee to go with your morning toast?)

Even in areas with good sanitation – we are still facing polluted water supplies from chemical and oil spills, some of which are accidents and others of which are purposeful dumping. And recently, Flint, Michigan has been in the news due its water crisis that developed when government officials switched water supplies for residents, and inadvertently introduced lead and iron into the system.

In drought-stricken areas of the world, water is appreciated and not taken for granted. Water planning, and the reliability of sanitation services, is a worldwide necessity. We must all consciously use and conserve water. For example, Australia, as the driest inhabited continent, is very keen on using its limited water resources wisely.

The traditional method for sterilizing water has been the use of a mercury lamp. You flash the mercury lamp on the water, and it kills the bacteria in the water. But the problem with mercury lamps is that they are prone to breakage, and if you get a mercury bulb in the water, the mercury contamination becomes a worse problem than the bacteria that was in the water.

So how do we provide drinkable water?

There is a movement to using Deep UV LED Technology for purifying water. The electromagnetic spectrum of deep UV light is created from an LED chip. When used in water purification and filtration, UV ultraviolet light is an effective method for reducing harmful bacteria, chemicals and microbes.

The UV light actually sterilizes the water; it doesn’t kill the bacteria in the water, but keeps the bacteria from reproducing. This prevents intestinal problems when the water is swallowed.

Huge investments are being made to develop new sanitation systems. As part of their Water, Sanitation & Hygiene program, the Bill & Melinda Gates Foundation has initiated a “Reinvent the Toilet Challenge,” to bring sustainable sanitation solutions to the billions of people worldwide who do not have access to safe, affordable sanitation. One of the developments involves using solar panels to create energy for purifying water with deep UV technology. The toilet water becomes drinkable.

Imagine having water-carrying containers with a UV light inside the bottle. You could fill the container with “contaminated” water, switch on the light, and the water would be purified and made drinkable.

There are limited resources in the world for drinkable water – and these sources are

dwindling. As the population increases, the need for water increases, not just for human consumption, but for agricultural and animal use, too. We could face some serious problems in the future as we continue to consume our limited water supplies.

Deep UV LED technology can help in providing drinkable water and sanitation services for all our needs. None of us could survive without a clean water supply.

What are your thoughts? Do you even think about your water supply when you are filling your glass at the water faucet? How can we work together to preserve our water supply?

by Jim Greig, Global Sales and Marketing Manager Electronic Materials, LORD Corporation

As we enter the mid-point through the calendar year, many of us are in a position in which we are defending sales compared to estimated plan. Or, maybe we are looking at how to fine-tune opportunities for the balance of 2015, ensuring maximum profit and potential for 2016. While these tasks are necessary, it is also key to look at your plans from a customer perspective. Regardless of what the balance sheet shows, are you taking care of business from the standpoint of your customers?

In this perplexing industry of ours, I have seen a growing trend of focusing more on new sales and growth, and less on taking care of existing customers. This is especially a challenge for those with large market share, as complacency can quickly become the standard. Do you show your customers how much you value their business, no matter how long you have worked together? One of my goals is for our customers to feel as if I wake up each day with the goal of earning their business once again by listening to their ever-changing needs.

No matter the industry, the pressure to lower costs is paramount, adding pressure throughout every step in the supply chain. To this end, many have simply accepted that schedules and budgets won’t be met. While this may or may not be the case, it is key for suppliers to be flexible, recognizing that forecasts and specifications change, so being adaptable is simply expected. However, flexibility should fall under a premise of trust and a shared common vision. Budgets and schedules can and should be met – a reality if the focus is on the relationship, not merely the profit.

At LORD Corporation, our goal is to build a relationship, not simply grow sales. The sales will happen if we work together to meet the needs of your customers, fine-tuning one of our existing solutions or developing one based on our decades of experience. I look forward to helping you develop your own customer relationships through our partnership efforts.

by Jim Greig, Global Sales and Marketing Manager Electronic Materials, LORD Corporation

Since Thomas Edison’s development of the first functional incandescent lightbulb in the late 1800s, the Edison screw bulb is how we have illuminated our homes and businesses.

Now, more than 125 years later, the lighting industry is undergoing another profound change – the directive to cease manufacturing incandescent bulbs. As of January 1, 2014, manufacturers could no longer legally make 40-, 60- or 100-watt incandescent lightbulbs for sale in the U.S.

So there you have it – you can only purchase an incandescent bulb until the supply runs out. Even if you have stockpiled a huge supply of incandescent bulbs, you’ll eventually have to replace them – with another type of light source, such as an LED bulb.

But is the LED industry doing all it can to keep prices amenable for the average consumer? Are they educating the public on how to buy LED lamps and helping them to understand the benefits? Are they standardizing LED lighting terminology? Are design changes to the LED bulb necessary or even viable?

I lie awake at night (with the lights out) thinking about these questions. I don’t really have the answers, but I think the questions need to be asked.

From a supplier’s perspective, the price pressure from LED manufacturers is getting really crazy. There is a lot of pressure from manufacturers to bring the costs down for materials used to manufacture the LED bulbs and fixtures. Manufacturers are looking to lower production costs so they can lower the price and spur mass adoption by the public.

And I get that – but I’m also concerned that if we drive down prices too far, are we risking quality just to make a cheap LED bulb? Are manufacturers cutting corners in production and not testing to specifications?

At what point do we say that there is no more money that can be squeezed out of the material suppliers – the price is the price. What is the tipping point? Price is being driven out of everything – at what point does it become untenable for a supplier to supply materials?

I believe there are three areas where the LED industry needs to update its thinking: design, terminology and education.

• Design: Perhaps there are there other ways to bring down the price of LED bulbs. Are we “stuck” with the design we have been using. Does the LED bulb have to be on the Edison screw-in connector base? In Europe, they use a different type of base – and maybe that design is more cost-effective. Is it purely a material cost that will drive down the cost of LED bulbs, or do we need a fundamental shift in design? Realistically, it seems that it would not be practical to begin changing the Edison screw-bulb design. Maybe some innovative lighting designer might be able to invent an adaption of the socket or lamp fixture – make some fundamental changes in the design of a bulb.

• Terminology: There is a lot of confusion among consumers about which LED bulb to purchase. Has the LED industry sufficiently articulated the payback period of the bulb so that consumers understand the benefits? There are no standards among the LED manufacturers for terminology describing LED bulbs. The packaging descriptions can be very confusing to consumers. Should you buy a 10-watt LED bulb or the 60-watt equivalent? And what does an 8-watt or 12-watt bulb mean in relation to how much light output is expected? What does lumens-per-watt mean? I don’t think that the consumer really understands how to purchase an LED bulb.

• Education: Is the LED industry educating the consumer on which LED bulb is right one to buy? Has the LED industry sufficiently articulated the payback period of the bulb so that consumers understand the benefits? I’m not seeing a lot of advertisements, literature or public service announcements making the case for how much energy or money is saved with the purchase of an LED bulb.

How do we drive mass adoption? LED manufacturers are trying to find the “hook” that will attract the consumer, but how can they do that if they are not working together as an industry?

Are we inadvertently developing a “contraband” industry of illegal LED bulb sales? When LED bulbs do go on sale, many of the retailers have to limit the amount that can be purchased to prevent mass purchases that are then resold online or in a “back alley.”

So instead of considering changes to LED bulb design, or working on industry standards, or developing educational programs for consumers – is it fair for manufacturers to keep asking the supplier to charge less for its products? Suppliers are also hit every year by rising raw material costs and labor and production labor costs – but we are still being asked to keep our prices down.

It’s all about costs. Everyone wants to make a profit at the end of the year – but if no one does – no one wins and everyone loses.

by Jim Greig, Global Sales and Marketing Manager Electronic Materials, LORD Corporation

I recently had a conversation with my 13-year-old daughter about fossil fuels. The discussion was prompted by what she is learning in school – how the world is being depleted of natural resources and which alternative energy options are viable for the future. Even at a very young age, children are beginning to understand that dependence on fossil fuels for their generation and for their children’s generation is not practical. It’s not just the “cool” thing anymore to be into alternative energy; it is imperative.

Awareness of the exhaustion of fossil fuels, along with legislated emission standards throughout the world, is driving the alternative viewpoint towards alternative energy and electric vehicles. The auto industry is starting to take note of the world’s “greenification” as it develops hybrid vehicles and looks to fuel cells as a potential offset.

In addition to the emerging interest in electric vehicles for personal use, other enterprises are also considering alternatives to gas-fueled transport. Companies such as UPS and Fed-Ex are contemplating electrifying their trucks, which would be especially efficient for the type of “start-stop” driving that is done as packages are delivered. Electrification of school buses and public transportation is a big target for electrification, especially for reducing air pollution in city and suburban environments.

As electric vehicle technology advances and the cost of ownership becomes more feasible for the average driver, do we have the infrastructure available for recharging the vehicles as drivers go about their daily business? Right now, we don’t.

Just as we have gas stations on almost every corner in major cities and suburban areas, and “rest” stops along the highways, the U.S. will need to have a network of charging stations situated along roadsides and throughout cities and towns. While OEMs are working on bringing down the cost of electric vehicles, the infrastructure for charging the electric vehicles needs to be established.

Awareness of the exhaustion of fossil fuels, along with legislated emission standards throughout the world, is driving the alternative viewpoint towards alternative energy and electric vehicles.

One of the major drawbacks to the acceptance of electric vehicles is “range anxiety.” Yes, you can charge your electric vehicle in your home and it will be operational for 100-to-200 miles before needing a recharge. So while you can calculate your driving distance ahead of time before you will need a recharge, how much easier would it be to know that a recharging station is conveniently available? That is the key to mass adoption of electric vehicles – charging stations accessible everywhere in the U.S.

With a charging station infrastructure in place, electric vehicles become a viable option for both short and long journeys – local trips to school or work or the grocery store, and longer drives to for vacation or a business trip.

So the question is: Do you wait for more consumers to buy electric vehicles as the prices become more palatable and then begin to establish charging stations through the U.S.? or Do you make the investment in the charging stations now so they will be ready for the electric vehicle users?

Children in school are already mindful of the fact that the world’s resources are coming to an end, and they will be the driving force towards alternative energy use. Is the U.S. culture ready for the infrastructure changes that will be necessary for electric vehicle transportation?

For more information on how LORD technology can help electric vehicle companies save money and become more efficient, please contact us.