Stabilising the world’s deepest open pit mine

Meet the geotechnical expert improving mine safety through international collaboration

Serdar is a geotechnical specialist whose expertise has taken him around the world.

In his latest role at our Kennecott operations in Utah in the United States, he’s achieved some incredible advancements for safety and efficiency, while mentoring the next generation of engineers.

Serdar is a RioExpert in our RioExcel program – a promotion pathway for our technical specialists, offering an alternative path for career progression other than leading large teams.

RioExcel focuses on building and sharing RioExperts' expertise while being recognised as a leader in their field.

"I’ve always sought out new challenges and opportunities to apply my expertise as a geotechnical engineer.

Prior to joining Rio Tinto, I’d worked and been involved with projects for 9 years in many countries, including China, Romania, Greece and Turkey.

Each stint broadened my understanding of geotechnical engineering and prepared me for the unique challenges at Rio Tinto Kennecott.

While presenting a technical paper in international conferences, I met specialists from Kennecott who saw potential in my skills. I was excited, as Bingham Canyon mine at Kennecott is the deepest open pit mine globally, and presented an array of geotechnical challenges.

In my current role, I oversee geotechnical studies for Kennecott. I find satisfaction in bridging technical expertise with operational efficiency.

Collaborating with various teams, both on-site and at our corporate office in Salt Lake City, allows me to contribute to the mine's stability while enhancing safety protocols and operational efficiency.

My role primarily revolves around ensuring slope stability, which is crucial given the mine's depth. I'm part of the long-range geotechnical team, so I work on studies that shape the mine's future and extend its lifespan, including expansion projects.

I find projects that are pivotal to the mine’s future very satisfying to work on.

Participating in the RioExcel program as a RioExpert has been a transformative experience. It's not just about personal recognition; it’s about fostering a culture of knowledge-sharing and mentorship.

Being a RioExpert means I'm able to help out in other areas of the business with challenges and connect with people to assist with their projects. It's already provided some great networking opportunities for me, and it’s encouraged me to step up and give the best of myself, knowing I'm helping to potentially guide the next generation of Rio Tinto’s technical experts.

By sharing insights and best practices, we can collectively drive positive change within the mining industry and beyond.

Serdar presenting his project work at a conference.

Serdar presenting his project work at a conference.

Serdar on site at Bingham Canyon at Kennecott in Utah, United States.

Serdar on site at Bingham Canyon at Kennecott in Utah, United States.

Serdar with his family.

Serdar with his family.

One of my proudest career achievements was developing and implementing the Geotechnical Verification Process at Kennecott.

There was no previous benchmark for this kind of process, and I designed and implemented it myself, with help from colleagues.

It’s now enhancing safety at Kennecott, and other operations around the world have started using it too, including Oyu Tolgoi in Mongolia.

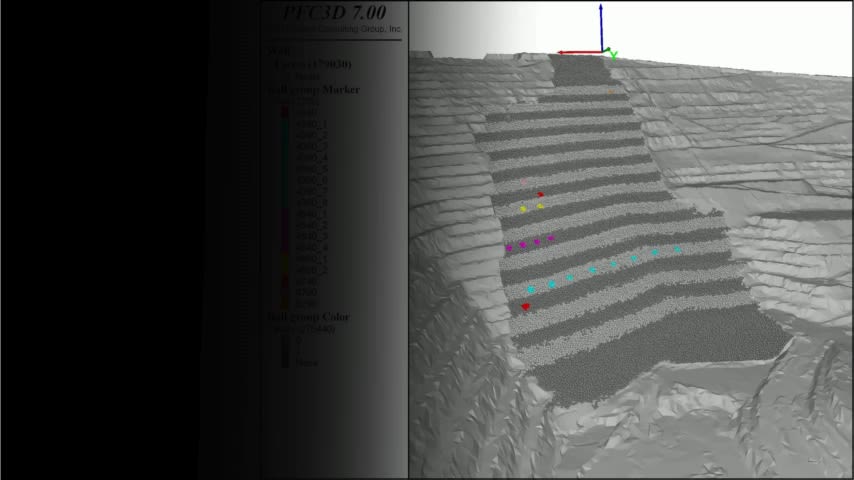

Another project I was particularly proud of was the Particle Flow Code Modeling of Failure Run-out Initiative.

We designed a new way to model a 500-meter slope failure at Bingham Canyon in 2021.

In May 2021, Rio Tinto’s Bingham Canyon Mine experienced a 21 Mt slope collapse referred to as the ‘Leo’ failure. Early detection of the initial slope movement and prediction of the collapse by the mine's integrated monitoring systems allowed for safe evacuation of staff and equipment.

The mine technical services manager at the time challenged us to model the progression and dynamics of the 21 million tons of runout to use it for rebuilding the ore control block model.

We didn’t have enough data to model properly using existing methods, so I found a particle flow code that was heavily used in the space, nuclear waste storage, and process engineering industries.

I collaborated with a French engineer working in these sectors who could help us apply it to a mining model. With very limited budget for the project, we contributed to a big saving in operational efficiency at Kennecott.

I also presented it at international conferences and other mine sites, including Escondida in Chile and Iron Ore Western Australia, which led to the model being adopted by other industry players, validating the impact of our work.

Geotechnical engineering is all about trying to find efficiencies – looking for ways to increase mine safety while saving money in operations.

So by challenging existing norms and advocating for innovative solutions, I aim to establish safe and stable mine designs that optimise ore delivery and align with long-term mine plans.

My goal is to continue to serve as a catalyst for industry innovation, now and in the future.

Last updated: 15 May 2024