Abstract

Concrete construction strategies can be material-intensive and labour-intensive and often rely on formwork that produces material waste. 3D printing (3DP) technologies could reduce the materials and time needed in concrete construction and could enable designs to optimize thermal management, energy efficiency and structural monitoring relative to formwork-based construction strategies. In this Review, we discuss 3D concrete printing and its application in construction. Large gantry printers and robotic arms have been used in the construction of houses (~100 m2), buildings (exceeding 1,000 m2) and other infrastructures, including bridges with spans up to 30 m. Advances in design and printer control, such as using topological optimization, allow for material efficiency (saving up to 70% materials) and use of features for thermal management and incorporation of vegetation into buildings. Strategies to integrate sensors for structural monitoring and materials for energy storage and thermal management of 3DP are also being developed. For example, self-sensing 3DP concrete has been integrated for structural health monitoring, and there are efforts to incorporate phase change materials to enhance thermal management. However, concrete 3DP ink has a high proportion of cement (owing to the need to balance pumpability and extrudability with buildability during printing), which increases the embodied carbon associated with 3DP concrete construction. Low-carbon inks and use of waste-derived materials are, therefore, needed to reduce the life-cycle impact and embodied carbon of 3DP concrete structures.

Key points

-

3D printing (3DP) concrete construction technologies enable materials efficiency and structural integrity in designs. Through the use of topological optimization, more than 50% of material savings relative to conventional construction methods have been reported.

-

Owing to extrudability, pumpability and buildability constraints, printable inks require more cement than conventional concrete (often > 40% of the volume).

-

Low-carbon inks and materials reuse are being developed to mitigate the environmental impact associated with increased cement usage.

-

3DP can enable structural designs to be multifunctional and integrate thermal management, structural monitoring strategies and green walls or other vegetation.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

World Green Building Council. Beyond the Business Case Report https://worldgbc.org/wp-content/uploads/2022/08/WorldGBC-Beyond-the-Business-Case.pdf (World Green Building Council, 2021).

Habert, G. et al. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 1, 559–573 (2020).

Hyun, C., Jin, C., Shen, Z. & Kim, H. Automated optimization of formwork design through spatial analysis in building information modeling. Autom. Constr. 95, 193–205 (2018).

Raza, M. H., Besklubova, S. & Zhong, R. Y. Economic analysis of offsite and onsite 3D construction printing techniques for low-rise buildings: a comparative value stream assessment. Addit. Manuf. 89, 104292 (2024).

Li, W., Lin, X., Bao, D. & Xie, Y. A review of formwork systems for modern concrete construction. Structures 38, 52–63 (2022).

Hao, J., Chen, Z., Zhang, Z. & Loehlein, G. Quantifying construction waste reduction through the application of prefabrication: a case study in Anhui, China. Environ. Sci. Pollut. Res. 28, 24499–24510 (2021).

Churkina, G. et al. Buildings as a global carbon sink. Nat. Sustain. 3, 269–276 (2020).

Hanifa, M., Agarwal, R., Sharma, U., Thapliyal, P. C. & Singh, L. P. A review on CO2 capture and sequestration in the construction industry: emerging approaches and commercialised technologies. J. CO2 Utilization 67, 102292 (2023).

Petersen, K. H., Napp, N., Stuart-Smith, R., Rus, D. & Kovac, M. A review of collective robotic construction. Sci. Robot. 4, eaau8479 (2019). Reviews collective robotic construction and multirobot systems for large-scale, adaptable and scalable construction tasks.

Lu, W. et al. Digital technologies for construction sustainability: status quo, challenges, and future prospects. npj Mater. Sustain. 2, 10 (2024).

Zhang, K. et al. Aerial additive manufacturing with multiple autonomous robots. Nature 609, 709–717 (2022). Describes an autonomous aerial additive manufacturing system, enabling scalable, untethered 3D printing in remote and hard-to-access locations.

Khan, M. S., Sanchez, F. & Zhou, H. 3-D printing of concrete: beyond horizons. Cem. Concr. Res. 133, 106070 (2020).

Dong, E. et al. Printing large size eggshell-shaped elements with ultra-high-performance concrete: from material design to structural bearing capacity assessment. Constr. Build. Mater. 462, 139983 (2025).

Wang, S., Liong, S., Gan, Y. & Sheng, Y. Cost-effective concrete fabrication for large irregularly shaped architectural structures. Autom. Constr. 156, 105119 (2023).

Han, Y., Yang, Z., Ding, T. & Xiao, J. Environmental and economic assessment on 3D printed buildings with recycled concrete. J. Clean. Prod. 278, 123884 (2021).

Wang, X. et al. Concrete 3D printing technology for sustainable construction: a review on raw material, concrete type and performance. Dev. Built Environ. 17, 100378 (2024).

Bi, M., Tran, P., Xia, L., Ma, G. & Xie, Y. M. Topology optimization for 3D concrete printing with various manufacturing constraints. Addit. Manuf. 57, 102982 (2022). Develops a topology optimization framework for 3D printing concrete construction with enhanced self-support, continuous extrusion and material anisotropy.

Ichihara, N. & Ueda, M. 3D-printed high-toughness composite structures by anisotropic topology optimization. Compos. Pt B Eng. 253, 110572 (2023).

De Schutter, G. et al. Vision of 3D printing with concrete — technical, economic and environmental potentials. Cem. Concr. Res. 112, 25–36 (2018).

Gibson, I. et al. Additive Manufacturing Technologies Vol. 17 (Springer, 2021).

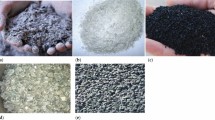

Bhattacherjee, S. et al. Sustainable materials for 3D concrete printing. Cem. Concr. Compos. 122, 104156 (2021).

Weng, Y., Li, M., Wong, T. N. & Tan, M. J. Synchronized concrete and bonding agent deposition system for interlayer bond strength enhancement in 3D concrete printing. Autom. Constr. 123, 103546 (2021).

Zhang, X. et al. Large-scale 3D printing by a team of mobile robots. Autom. Constr. 95, 98–106 (2018).

Zuo, Z. et al. Propelling the widespread adoption of large-scale 3D printing. Nat. Rev. Mater. 9, 754–756 (2023). Highlights advancements in large-scale 3D printing, emphasizing material, process and printer innovations necessary for construction automation of complex and multifunctional structures.

Sovetova, M. & Kaiser Calautit, J. Thermal and energy efficiency in 3D-printed buildings: review of geometric design, materials and printing processes. Energy Build. 323, 114731 (2024).

Davila Delgado, J. M. et al. Robotics and automated systems in construction: understanding industry-specific challenges for adoption. J. Build. Eng. 26, 100868 (2019).

Khoshnevis, B. Automated construction by contour crafting — related robotics and information technologies. Autom. Constr. 13, 5–19 (2004).

Keating, S. J., Leland, J. C., Cai, L. & Oxman, N. Toward site-specific and self-sufficient robotic fabrication on architectural scales. Sci. Robot. 2, eaam8986 (2017).

Loveridge, R. & Coray, T. Robots on construction sites: the potential and challenges of on-site digital fabrication. Sci. Robot. 2, eaan3674 (2017).

Khoshnevis, B., Bukkapatnam, S., Kwon, H. & Saito, J. Experimental investigation of contour crafting using ceramics materials. Rapid Prototyp. J. 7, 32–42 (2001).

Burger, J. et al. Design and fabrication of optimised ribbed concrete floor slabs using large scale 3D printed formwork. Autom. Constr. 144, 104599 (2022).

Xiao, J. et al. Large-scale 3D printing concrete technology: current status and future opportunities. Cem. Concr. Compos. 122, 104115 (2021).

Chermprayong, P., Zhang, K., Xiao, F. & Kovac, M. An integrated delta manipulator for aerial repair: a new aerial robotic system. IEEE Robot. Autom. Mag. 26, 54–66 (2019).

Werfel, J., Petersen, K. & Nagpal, R. Designing collective behavior in a termite-inspired robot construction team. Science 343, 754–758 (2014).

Miriyev, A. & Kovač, M. Skills for physical artificial intelligence. Nat. Mach. Intell. 2, 658–660 (2020).

Lin, T.-H., Chang, C.-T., Yang, B.-H., Hung, C.-C. & Wen, K.-W. AI-powered shotcrete robot for enhancing structural integrity using ultra-high performance concrete and visual recognition. Autom. Constr. 155, 105038 (2023).

Qin, S. et al. AIstructure-Copilot: assistant for generative AI-driven intelligent design of building structures. Smart Constr. 1, 1–20 (2024).

Zheng, Y., Gao, Y., Lu, S. & Mosalam, K. M. Multistage semisupervised active learning framework for crack identification, segmentation, and measurement of bridges. Comput. Civ. Infrastruct. Eng. 37, 1089–1108 (2022).

Fei, Y., Liao, W., Lu, X. & Guan, H. Knowledge‐enhanced graph neural networks for construction material quantity estimation of reinforced concrete buildings. Comput. Civ. Infrastruct. Eng. 39, 518–538 (2023).

Lee, D., Lee, S. H., Masoud, N., Krishnan, M. S. & Li, V. C. Integrated digital twin and blockchain framework to support accountable information sharing in construction projects. Autom. Constr. 127, 103688 (2021).

Anane, W., Iordanova, I. & Ouellet-Plamondon, C. BIM-driven computational design for robotic manufacturing in off-site construction: an integrated Design-to-Manufacturing (DtM) approach. Autom. Constr. 150, 104782 (2023).

Zhang, W.-J. et al. Semi-supervised learning approach for construction object detection by integrating super-resolution and mean teacher network. J. Infrastruct. Intell. Resil. 3, 100095 (2024).

Wang, Z., Zhang, Y., Mosalam, K. M., Gao, Y. & Huang, S. L. Deep semantic segmentation for visual understanding on construction sites. Comput. Civ. Infrastruct. Eng. 37, 145–162 (2021).

Johns, R. L. et al. A framework for robotic excavation and dry stone construction using on-site materials. Sci. Robot. 8, eabp9758 (2023).

Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 112, 76–85 (2018).

Zhang, Y. et al. A potential active rheology control approach for 3D printable cement-based materials: coupling of temperature and viscosity modifiers. Cem. Concr. Compos. 149, 105496 (2024).

Gao, H. et al. Rheological behavior of 3D printed concrete: influential factors and printability prediction scheme. J. Build. Eng. 91, 109626 (2024).

Roussel, N., Ovarlez, G., Garrault, S. & Brumaud, C. The origins of thixotropy of fresh cement pastes. Cem. Concr. Res. 42, 148–157 (2012).

Liu, C. et al. Influence of HPMC and SF on buildability of 3D printing foam concrete: from water state and flocculation point of view. Composites Pt B Eng. 242, 110075 (2022).

Chen, Y. et al. Systematical investigation of rheological performance regarding 3D printing process for alkali-activated materials: effect of precursor nature. Cem. Concr. Compos. 128, 104450 (2022).

Tay, Y. W. D., Qian, Y. & Tan, M. J. Printability region for 3D concrete printing using slump and slump flow test. Compos. Pt B Eng. 174, 106968 (2019).

Chen, Y. et al. Extending applicability of 3D-printable geopolymer to large-scale printing scenario via combination of sodium carbonate and nano-silica. Cem. Concr. Compos. 145, 105322 (2024).

Cheng, H., Radlińska, A., Hillman, M., Liu, F. & Wang, J. Modeling concrete deposition via 3D printing using reproducing kernel particle method. Cem. Concr. Res. 181, 107526 (2024).

Chen, Y. et al. A mechanical characteristic capture method considering printing configurations for buildability modeling in concrete 3D printing. Addit. Manuf. 94, 104462 (2024).

Asghari, Y., Mohammadyan-Yasouj, S. E., Petrů, M., Ghandvar, H. & R. Koloor, S. S. 3D printing and implementation of engineered cementitious composites — a review. Case Stud. Constr. Mater. 21, e03462 (2024).

Liu, Y., Lu, C., Hu, X. & Shi, C. Effect of silica fume on rheology of slag-fly ash-silica fume-based geopolymer pastes with different activators. Cem. Concr. Res. 174, 107336 (2023).

Gupta, S., Tulliani, J.-M. & Kua, H. W. Carbonaceous admixtures in cementitious building materials: effect of particle size blending on rheology, packing, early age properties and processing energy demand. Sci. Total Environ. 807, 150884 (2022).

Xu, Y. et al. Correlation of interlayer properties and rheological behaviors of 3DPC with various printing time intervals. Addit. Manuf. 47, 102327 (2021).

Pan, T., Guo, R., Jiang, Y. & Ji, X. How do the contact surface forces affect the interlayer bond strength of 3D printed mortar? Cem. Concr. Compos. 133, 104675 (2022).

Wallevik, O. H. & Wallevik, J. E. Rheology as a tool in concrete science: the use of rheographs and workability boxes. Cem. Concr. Res. 41, 1279–1288 (2011).

Liu, C. et al. Effect of sulphoaluminate cement on fresh and hardened properties of 3D printing foamed concrete. Compos. Pt B Eng. 232, 109619 (2022).

Ibrahim, K. A., van Zijl, G. P. A. G. & Babafemi, A. J. Influence of limestone calcined clay cement on properties of 3D printed concrete for sustainable construction. J. Build. Eng. 69, 106186 (2023).

Nodehi, M., Ozbakkaloglu, T. & Gholampour, A. Effect of supplementary cementitious materials on properties of 3D printed conventional and alkali-activated concrete: a review. Autom. Constr. 138, 104215 (2022).

Chu, S. H., Yang, E. H. & Unluer, C. Development of nanofiber reinforced reactive magnesia-based composites for 3D printing. Constr. Build. Mater. 366, 130270 (2023).

Perrot, A. et al. Snapshot on 3D printing with alternative binders and materials: Earth, geopolymers, gypsum and low carbon concrete. Cem. Concr. Res. 185, 107651 (2024). Reviews the alternative low-carbon printable inks for 3DP and analyses their potential to reduce carbon footprints and optimize structural performance in 3DP.

Harbouz, I., Yahia, A., Roziere, E. & Loukili, A. Printing quality control of cement-based materials under flow and rest conditions. Cem. Concr. Compos. 138, 104965 (2023).

Zhang, J. et al. Alterations in rheo-viscoelastic properties of cement composites with biochar incorporation as bio-based admixture. Constr. Build. Mater. 439, 137358 (2024).

Ma, X., Tan, L., Lu, Y., Yao, W. & Wei, Y. Upcycling of waste plasterboard for the synthesis of high-quality gypsum-based 3D printing powder. Constr. Build. Mater. 373, 130846 (2023).

Zhang, H., Xiao, J., Duan, Z., Zou, S. & Xia, B. Effects of printing paths and recycled fines on drying shrinkage of 3D printed mortar. Constr. Build. Mater. 342, 128007 (2022).

Pasupathy, K., Ramakrishnan, S. & Sanjayan, J. 3D concrete printing of eco-friendly geopolymer containing brick waste. Cem. Concr. Compos. 138, 104943 (2023).

Rodriguez Mendez, Q., Fuss, S., Lück, S. & Creutzig, F. Assessing global urban CO2 removal. Nat. Cities 1, 413–423 (2024).

De Vlieger, J., Boehme, L., Blaakmeer, J. & Li, J. Buildability assessment of mortar with fine recycled aggregates for 3D printing. Constr. Build. Mater. 367, 130313 (2023).

Liu, H. et al. 3D printing concrete with recycled coarse aggregates: the influence of pore structure on interlayer adhesion. Cem. Concr. Compos. 134, 104742 (2022).

Saruhan, V., Keskinateş, M. & Felekoğlu, B. A comprehensive review on fresh state rheological properties of extrusion mortars designed for 3D printing applications. Constr. Build. Mater. 337, 127629 (2022).

Weng, Y., Li, M., Zhang, D., Tan, M. J. & Qian, S. Investigation of interlayer adhesion of 3D printable cementitious material from the aspect of printing process. Cem. Concr. Res. 143, 106386 (2021).

Yuan, P. F., Zhan, Q., Wu, H., Beh, H. S. & Zhang, L. Real-time toolpath planning and extrusion control (RTPEC) method for variable-width 3D concrete printing. J. Build. Eng. 46, 103716 (2022).

Breseghello, L. & Naboni, R. Toolpath-based design for 3D concrete printing of carbon-efficient architectural structures. Addit. Manuf. 56, 102872 (2022).

Carneau, P., Mesnil, R., Baverel, O. & Roussel, N. Layer pressing in concrete extrusion-based 3D-printing: experiments and analysis. Cem. Concr. Res. 155, 106741 (2022).

Lao, W., Li, M. & Tjahjowidodo, T. Variable-geometry nozzle for surface quality enhancement in 3D concrete printing. Addit. Manuf. 37, 101638 (2021).

Muthukrishnan, S., Ramakrishnan, S. & Sanjayan, J. Technologies for improving buildability in 3D concrete printing. Cem. Concr. Compos. 122, 104144 (2021).

Liu, J. et al. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 57, 2457–2483 (2018).

Zhuang, Z. et al. A comprehensive review of sustainable materials and toolpath optimization in 3D concrete printing. npj Mater. Sustain. 2, 12 (2024).

Wethyavivorn, B., Surit, S., Thanadirek, T. & Wethyavivorn, P. Topology optimization-based reinforced concrete beams: design and experiment. J. Struct. Eng. 148, 04022154 (2022).

Pressmair, N. & Kromoser, B. A contribution to resource-efficient construction: design flow and experimental investigation of structurally optimised concrete girders. Eng. Struct. 281, 115757 (2023).

Liu, Y., Jewett, J. L. & Carstensen, J. V. in Second RILEM International Conference on Concrete and Digital Fabrication (eds Bos, F. P., Lucas, S. S., Wolfs, R. J. M. & Salet, T. A. M.) Vol. 28, 601–611 (Springer International Publishing, 2020).

Li, Y. et al. FloatArch: a cable-supported, unreinforced, and re-assemblable 3D-printed concrete structure designed using multi-material topology optimization. Addit. Manuf. 81, 104012 (2024).

Yang, W., Wang, L., Ma, G. & Feng, P. An integrated method of topological optimization and path design for 3D concrete printing. Eng. Struct. 291, 116435 (2023).

Wu, J., Sigmund, O. & Groen, J. P. Topology optimization of multi-scale structures: a review. Struct. Multidiscip. Optim. 63, 1455–1480 (2021).

Aage, N., Andreassen, E., Lazarov, B. S. & Sigmund, O. Giga-voxel computational morphogenesis for structural design. Nature 550, 84–86 (2017). Introduces a giga-voxel tool for high-resolution optimization of structural designs, with future potential for large-scale 3D printing integration.

Dias, J. M., da Silva, F. S. C. P., Gasik, M., Miranda, M. G. M. & Bartolomeu, F. J. F. Unveiling additively manufactured cellular structures in hip implants: a comprehensive review. Int. J. Adv. Manuf. Technol. 130, 4073–4122 (2023).

Peng, B. et al. Machine learning-enabled constrained multi-objective design of architected materials. Nat. Commun. 14, 6630 (2023). Provides a machine-learning-enabled framework for the constrained multi-objective design of 3D printed architected materials.

Zhu, Z., Ng, D. W. H., Park, H. S. & McAlpine, M. C. 3D-printed multifunctional materials enabled by artificial-intelligence-assisted fabrication technologies. Nat. Rev. Mater. 6, 27–47 (2020).

Goh, G. D., Sing, S. L. & Yeong, W. Y. A review on machine learning in 3D printing: applications, potential, and challenges. Artif. Intell. Rev. 54, 63–94 (2020).

Qi, X., Chen, G., Li, Y., Cheng, X. & Li, C. Applying neural-network-based machine learning to additive manufacturing: current applications, challenges, and future perspectives. Engineering 5, 721–729 (2019).

Gobert, C., Reutzel, E. W., Petrich, J., Nassar, A. R. & Phoha, S. Application of supervised machine learning for defect detection during metallic powder bed fusion additive manufacturing using high resolution imaging. Addit. Manuf. 21, 517–528 (2018).

Chang, Z., Zhang, H., Liang, M., Schlangen, E. & Šavija, B. Numerical simulation of elastic buckling in 3D concrete printing using the lattice model with geometric nonlinearity. Autom. Constr. 142, 104485 (2022).

Park, D., Lee, J., Lee, H., Gu, G. X. & Ryu, S. Deep generative spatiotemporal learning for integrating fracture mechanics in composite materials: inverse design, discovery, and optimization. Mater. Horiz. 11, 3048–3065 (2024).

Maruyama, I. & Lura, P. Properties of early-age concrete relevant to cracking in massive concrete. Cem. Concr. Res. 123, 105770 (2019).

Vanek, J., Galicia, J. A. G. & Benes, B. Clever support: efficient support structure generation for digital fabrication. Computer Graph. Forum 33, 117–125 (2014).

Jin, Z., Zhang, Z., Demir, K. & Gu, G. X. Machine learning for advanced additive manufacturing. Matter 3, 1541–1556 (2020).

Lowke, D. et al. Material–process interactions in particle bed 3D printing and the underlying physics. Cem. Concr. Res. 156, 106748 (2022).

Roussel, N., Spangenberg, J., Wallevik, J. & Wolfs, R. Numerical simulations of concrete processing: from standard formative casting to additive manufacturing. Cem. Concr. Res. 135, 106075 (2020).

Mohammad, A. S. & Biernacki, J. J. 2D stationary computational printing of cement-based pastes. Cem. Concr. Res. 159, 106866 (2022).

LaValle, S. M. Planning Algorithms (Cambridge Univ. Press, 2006).

Buswell, R. A., Leal de Silva, W. R., Jones, S. Z. & Dirrenberger, J. 3D printing using concrete extrusion: a roadmap for research. Cem. Concr. Res. 112, 37–49 (2018).

Gordon, W. J. & Hall, C. A. Transfinite element methods: blending-function interpolation over arbitrary curved element domains. Numerische Mathematik 21, 109–129 (1973).

Zhao, H. et al. Connected fermat spirals for layered fabrication. ACM Trans. Graph. 35, 1–10 (2016).

Li, S., Nguyen-Xuan, H. & Tran, P. Digital design and parametric study of 3D concrete printing on non-planar surfaces. Autom. Constr. 145, 104624 (2023).

Wong, N. H., Tan, C. L., Kolokotsa, D. D. & Takebayashi, H. Greenery as a mitigation and adaptation strategy to urban heat. Nat. Rev. Earth Environ. 2, 166–181 (2021).

Zhong, H.-Y. et al. Single-sided natural ventilation in buildings: a critical literature review. Build. Environ. 212, 108797 (2022).

Seuntjens, O., Belmans, B., Buyle, M. & Audenaert, A. A critical review on the adaptability of ventilation systems: current problems, solutions and opportunities. Build. Environ. 212, 108816 (2022).

Dubor, A. et al. in Humanizing Digital Reality: Design Modelling Symposium Paris 2017 (eds De Rycke, K. et al.) 383–393 (Springer Singapore, 2018).

Leschok, M. et al. 3D printing facades: design, fabrication, and assessment methods. Autom. Constr. 152, 104918 (2023).

Feng, J. et al. Fire-safe aerogels and foams for thermal insulation: from materials to properties. Adv. Mater. 37, e2411856 (2024).

Yi, H. & Kim, Y. Prototyping of 4D-printed self-shaping building skin in architecture: design, fabrication, and investigation of a two-way shape memory composite (TWSMC) façade panel. J. Build. Eng. 43, 103076 (2021).

de Rubeis, T., Ciccozzi, A., Giusti, L. & Ambrosini, D. On the use of 3D printing to enhance the thermal performance of building envelope — a review. J. Build. Eng. 95, 110284 (2024).

Li, Z., Xing, W., Sun, J., Feng, X. & Wang, H. Thermal network model for anisotropic heat transfer in 3D printed complex geometry structures. Build. Environ. 254, 111381 (2024).

Bentz, D. P. Transient plane source measurements of the thermal properties of hydrating cement pastes. Mater. Struct. 40, 1073–1080 (2007).

Sayyar, M., Weerasiri, R. R., Soroushian, P. & Lu, J. Experimental and numerical study of shape-stable phase-change nanocomposite toward energy-efficient building constructions. Energy Build. 75, 249–255 (2014).

Cui, H., Memon, S. A. & Liu, R. Development, mechanical properties and numerical simulation of macro encapsulated thermal energy storage concrete. Energy Build. 96, 162–174 (2015).

Memon, S. A., Cui, H., Zhang, H. & Xing, F. Utilization of macro encapsulated phase change materials for the development of thermal energy storage and structural lightweight aggregate concrete. Appl. Energy 139, 43–55 (2015).

Sarilak, D., Kerdlap, W., Embley, B., Chisti, Y. & Hansupalak, N. Model-based design, synthesis and use of thermally insulating mortar formulations for energy conservation in buildings. J. Clean. Prod. 276, 124287 (2020).

Strzałkowski, J., Stolarska, A., Kożuch, D. & Dmitruk, J. Hygrothermal and strength properties of cement mortars containing cenospheres. Cem. Concr. Res. 174, 107325 (2023).

Marani, A. & Nehdi, M. L. Integrating phase change materials in construction materials: critical review. Constr. Build. Mater. 217, 36–49 (2019).

Dinesh, A., Indhumathi, S. & Pichumani, M. Self-sensing cement composites for structural health monitoring: from know-how to do-how. Autom. Constr. 160, 105304 (2024).

Dinesh, A., Suji, D. & Pichumani, M. Self-sensing cementitious composite sensor with integrated steel fiber and carbonaceous powder for real-time application in large-scale infrastructures. Sens. Actuators A Phys. 353, 114209 (2023).

Chanut, N. et al. Carbon-cement supercapacitors as a scalable bulk energy storage solution. Proc. Natl Acad. Sci. USA 120, e2304318120 (2023).

Lyu, Q. et al. Energy storage properties and mechanical strengths of 3D printed porous concrete structural supercapacitors reinforced by electrodes made of carbon-black-coated Ni foam. Cem. Concr. Compos. 157, 105926 (2025).

Dinesh, A., Saravanakumar, P., Rahul Prasad, B. & Kilbert Raj, S. Carbon black based self-sensing cement composite for structural health monitoring — a review on strength and conductive characteristics. Mater. Today Proc. https://doi.org/10.1016/j.matpr.2023.03.661 (2023).

Jin, P. et al. Multifunctional cement-based composite with advanced self-sensing, electrothermal, and electrochemical properties. Adv. Funct. Mater. 35, 2411878 (2024).

Ding, S. et al. Self-heating ultra-high performance concrete with stainless steel wires for active deicing and snow-melting of transportation infrastructures. Cem. Concr. Compos. 138, 105005 (2023).

Nemova, D. et al. Experimental study on the thermal performance of 3D-printed enclosing structures. Energies 15, 4230 (2022).

Amran, M., Fediuk, R., Murali, G., Vatin, N. & Al-Fakih, A. Sound-absorbing acoustic concretes: a review. Sustainability 13, 10712 (2021).

Setaki, F. et al. 3D-printed sound absorbers: compact and customisable at broadband frequencies. Architect. Struct. Constr. 3, 205–215 (2023).

Chen, Z., Chong, Y. B., Lim, K. M. & Lee, H. P. Reconfigurable 3D printed acoustic metamaterial chamber for sound insulation. Int. J. Mech. Sci. 266, 108978 (2024).

Sheng, H., He, M.-X., Pueh Lee, H. & Ding, Q. Quasi-periodic sonic black hole with low-frequency acoustic and elastic bandgaps. Compos. Struct. 337, 118046 (2024).

Lyu, Q., Wang, Y. & Dai, P. Multilayered plant-growing concrete manufactured by aggregate-bed 3D concrete printing. Constr. Build. Mater. 430, 136453 (2024).

He, Y., Zhang, Y., Zhang, C. & Zhou, H. Energy-saving potential of 3D printed concrete building with integrated living wall. Energy Build. 222, 110110 (2020).

Lyu, Q., Dai, P., Zong, M., Zhu, P. & Liu, J. Plant-germination ability and mechanical strength of 3D printed vegetation concrete bound with cement and soil. Constr. Build. Mater. 408, 133587 (2023).

Chegut, A., Eichholtz, P. & Kok, N. The price of innovation: an analysis of the marginal cost of green buildings. J. Environ. Econ. Manag. 98, 102248 (2019).

Adresi, M. & Pakhirehzan, F. Evaluating the performance of self-sensing concrete sensors under temperature and moisture variations — a review. Constr. Build. Mater. 404, 132923 (2023).

Zhang, H., Hao, L., Zhang, S., Xiao, J. & Poon, C. S. Advanced measurement techniques for plastic shrinkage and cracking in 3D-printed concrete utilising distributed optical fiber sensor. Addit. Manuf. 74, 103722 (2023).

Banijamali, K. et al. Automated strength monitoring of 3D printed structures via embedded sensors. Autom. Constr. 166, 105681 (2024).

Gu, H. & Wei, Y. Environmental monitoring and landscape design of green city based on remote sensing image and improved neural network. Environ. Technol. Innov. 23, 101718 (2021).

Longo, A., Zappatore, M. & Bochicchio, M. A. Apollon: towards a citizen science methodology for urban environmental monitoring. Fut. Gener. Computer Syst. 112, 899–912 (2020).

Bong, S. H., Xia, M., Nematollahi, B. & Shi, C. Ambient temperature cured ‘just-add-water’ geopolymer for 3D concrete printing applications. Cem. Concr. Compos. 121, 104060 (2021).

Ghourchian, S., Butler, M., Krüger, M. & Mechtcherine, V. Modelling the development of capillary pressure in freshly 3D-printed concrete elements. Cem. Concr. Res. 145, 106457 (2021).

Xia, K. et al. Understanding and modeling the plastic deformation of 3D printed concrete based on viscoelastic creep behavior. Addit. Manuf. 84, 104132 (2024).

Vlachakis, C., McAlorum, J. & Perry, M. 3D printed cement-based repairs and strain sensors. Autom. Constr. 137, 104202 (2022).

Wang, L. & Aslani, F. Structural performance of reinforced concrete beams with 3D printed cement-based sensor embedded and self-sensing cementitious composites. Eng. Struct. 275, 115266 (2023).

Huang, X., Liu, Y., Huang, L., Onstein, E. & Merschbrock, C. BIM and IoT data fusion: the data process model perspective. Autom. Constr. 149, 104792 (2023).

Kumar, A. et al. Sensing technologies for monitoring intelligent buildings: a review. IEEE Sens. J. 18, 4847–4860 (2018).

Jiang, Y., Yin, S., Li, K., Luo, H. & Kaynak, O. Industrial applications of digital twins. Philos. Trans. A Math. Phys. Eng. Sci. 379, 20200360 (2021).

Moelich, G. M., Kruger, J. & Combrinck, R. Plastic shrinkage cracking in 3D printed concrete. Compos. Pt B Eng. 200, 108313 (2020).

Pan, Z. & Yu, Y. Learning multi-granular worker intentions from incomplete visual observations for worker–robot collaboration in construction. Autom. Constr. 158, 105184 (2024).

Cha, Y.-J., Ali, R., Lewis, J. & Büyüköztürk, O. Deep learning-based structural health monitoring. Autom. Constr. 161, 105328 (2024).

Abdelmageed, S., Abdelkhalek, S., Hussien, M. & Zayed, T. A hybrid simulation model for modules installation in modular integrated construction projects. Int. J. Constr. Manag. 24, 1407–1418 (2024).

An, D., Zhang, Y. X. & Yang, R. Numerical modelling of 3D concrete printing: material models, boundary conditions and failure identification. Eng. Struct. 299, 117104 (2024).

Nguyen, P. D., Nguyen, T. Q., Tao, Q. B., Vogel, F. & Nguyen-Xuan, H. A data-driven machine learning approach for the 3D printing process optimisation. Virtual Phys. Prototyp. 17, 768–786 (2022).

Dörfler, K. et al. Advancing construction in existing contexts: prospects and barriers of 3d printing with mobile robots for building maintenance and repair. Cem. Concr. Res. 186, 107656 (2024).

Weng, Y. et al. Comparative economic, environmental and productivity assessment of a concrete bathroom unit fabricated through 3D printing and a precast approach. J. Clean. Prod. 261, 121245 (2020).

Tinoco, M. P. et al. Life cycle assessment (LCA) and environmental sustainability of cementitious materials for 3D concrete printing: a systematic literature review. J. Build. Eng. 52, 104456 (2022).

Bedarf, P., Dutto, A., Zanini, M. & Dillenburger, B. Foam 3D printing for construction: a review of applications, materials, and processes. Autom. Constr. 130, 103861 (2021).

Hassan, H. et al. Towards innovative and sustainable buildings: a comprehensive review of 3D printing in construction. Autom. Constr. 163, 105417 (2024).

Mansuri, D., Chakraborty, D., Elzarka, H., Deshpande, A. & Gronseth, T. Building information modeling enabled cascading formwork management tool. Autom. Constr. 83, 259–272 (2017).

Batikha, M., Jotangia, R., Baaj, M. Y. & Mousleh, I. 3D concrete printing for sustainable and economical construction: a comparative study. Autom. Constr. 134, 104087 (2022).

Van Roijen, E., Miller, S. A. & Davis, S. J. Building materials could store more than 16 billion tonnes of CO2 annually. Science 387, 176–182 (2025).

Labianca, C. et al. A holistic framework of biochar-augmented cementitious products and general applications: technical, environmental, and economic evaluation. Environ. Res. 245, 118026 (2024).

Huang, Y. et al. 3D printing of topologically optimized wing spar with continuous carbon fiber reinforced composites. Compos. Pt B Eng. 272, 111166 (2024).

Rahemipoor, S. et al. Phase change materials incorporation into 3D printed geopolymer cement: a sustainable approach to enhance the comfort and energy efficiency of buildings. J. Clean. Prod. 417, 138005 (2023).

Alhumayani, H., Gomaa, M., Soebarto, V. & Jabi, W. Environmental assessment of large-scale 3D printing in construction: a comparative study between cob and concrete. J. Clean. Prod. 270, 122463 (2020).

Habibi, A., Buswell, R., Osmani, M. & Aziminezhad, M. Sustainability principles in 3D concrete printing: analysing trends, classifying strategies, and future directions. J. Build. Eng. 98, 111354 (2024).

Zhang, C. et al. Design of 3D printable concrete based on the relationship between flowability of cement paste and optimum aggregate content. Cem. Concr. Compos. 104, 103406 (2019).

Lowke, D. et al. Particle-bed 3D printing in concrete construction — possibilities and challenges. Cem. Concr. Res. 112, 50–65 (2018).

Zhang, C. et al. Mix design concepts for 3D printable concrete: a review. Cem. Concr. Compos. 122, 104155 (2021). Reviews the mix design concepts for 3D printable inks and material properties required for pumpability, extrudability and buildability in 3D printed applications.

Zhang, Y. et al. Comparison of printability and mechanical properties of rigid and flexible fiber-reinforced 3D printed cement-based materials. Constr. Build. Mater. 400, 132750 (2023).

Zhang, D. et al. Discontinuous micro-fibers as intrinsic reinforcement for ductile engineered cementitious composites (ECC). Compos. Pt B Eng. 184, 107741 (2020).

Dunant, C. F., Joseph, S., Prajapati, R. & Allwood, J. M. Electric recycling of Portland cement at scale. Nature 629, 1055–1061 (2024).

Kopitha, K., Rajeev, P., Sanjayan, J. & Elakneswaran, Y. CO2 sequestration and low carbon strategies in 3D printed concrete. J. Build. Eng. 99, 111653 (2025).

Zhong, K., Liu, Z. & Wang, F. Development of CO2 curable 3D printing materials. Addit. Manuf. 65, 103442 (2023).

Li, L. et al. Development of CO2-integrated 3D printing concrete. Constr. Build. Mater. 409, 134233 (2023).

El-Sayegh, S., Romdhane, L. & Manjikian, S. A critical review of 3D printing in construction: benefits, challenges, and risks. Arch. Civ. Mech. Eng. 20, 34 (2020).

Weger, D. et al. Building rethought — 3D concrete printing in building practice. Constr. Robot. 5, 203–210 (2021).

Tabassum, T. & Ahmad Mir, A. A review of 3D printing technology — the future of sustainable construction. Mater. Today Proc. 93, 408–414 (2023).

ISO/ASTM 52939:2023. Additive Manufacturing for Construction — Qualification Principles — Structural and Infrastructure Elements International Standard. American Society for Testing and Materials (ISO/ATSM) (2023).

T/CECS 786-2020. Technical Specification of Concrete 3D Printing (China Association for Engineering Construction Standardization (CECS), 2020).

T/CCPA 33 — 2022 (T/CBMF 183). Test Methods for Basic Mechanical Properties of 3D Printed Concrete (China Concrete & Cement-Based Products Association (CCPA), 2022).

T/CCPA 34 — 2022 (T/CBMF 184). Test Methods for Printability of 3D Printing Fresh Concrete (China Concrete & Cement-Based Products Association (CCPA), 2022).

USACE ECB 2021-13. Design and Construction of 3D Printed (Additive Construction) Concrete Structures (Engineering and Construction Bulletin (ECB), 2021).

Besklubova, S., Skibniewski, M. J. & Zhang, X. Factors affecting 3D printing technology adaptation in construction. J. Constr. Eng. Manag. 147, 04021026 (2021).

Robayo-Salazar, R., Mejía de Gutiérrez, R., Villaquirán-Caicedo, M. A. & Delvasto Arjona, S. 3D printing with cementitious materials: challenges and opportunities for the construction sector. Autom. Constr. 146, 104693 (2023).

Chemweno, P., Pintelon, L. & Decre, W. Orienting safety assurance with outcomes of hazard analysis and risk assessment: a review of the ISO 15066 standard for collaborative robot systems. Saf. Sci. 129, 104832 (2020).

Xu, M., Nie, X., Li, H., Cheng, J. C. P. & Mei, Z. Smart construction sites: a promising approach to improving on-site HSE management performance. J. Build. Eng. 49, 104007 (2022).

Fang, W. et al. Knowledge graph for identifying hazards on construction sites: integrating computer vision with ontology. Autom. Constr. 119, 103310 (2020).

Halder, S., Afsari, K., Chiou, E., Patrick, R. & Hamed, K. A. Construction inspection & monitoring with quadruped robots in future human–robot teaming: a preliminary study. J. Build. Eng. 65, 105814 (2023).

Asprone, D. et al. Rethinking reinforcement for digital fabrication with concrete. Cem. Concr. Res. 112, 111–121 (2018).

Mechtcherine, V. et al. A roadmap for quality control of hardening and hardened printed concrete. Cem. Concr. Res. 157, 106800 (2022).

Wang, C., Chen, B., Vo, T. L. & Rezania, M. Mechanical anisotropy, rheology and carbon footprint of 3D printable concrete: a review. J. Build. Eng. 76, 107309 (2023).

Rau, D. A., Williams, C. B. & Bortner, M. J. Rheology and printability: a survey of critical relationships for direct ink write materials design. Prog. Mater. Sci. 140, 101188 (2023).

Feys, D., De Schutter, G., Fataei, S., Martys, N. S. & Mechtcherine, V. Pumping of concrete: understanding a common placement method with lots of challenges. Cem. Concr. Res. 154, 106720 (2022).

Skempton, A. W. Portland cements, 1843–1887. Trans. Newcomen Soc. 35, 117–152 (1962).

Brown, J. M. WB Wilkinson (1819–1902) and His Place in the History of Reinforced Concrete (Taylor & Francis, 1966).

Lei, L., Hirata, T. & Plank, J. 40 years of PCE superplasticizers — history, current state-of-the-art and an outlook. Cem. Concr. Res. 157, 106826 (2022).

Hull, C. W. The birth of 3D printing. Res. Technol. Manag. 58, 25–30 (2015).

Leach, N. Curating the digital: an interview with MoMA’s Paola Antonelli. Architect. Des. 87, 26–33 (2017).

Khoshnevis, B., Russell, R., Kwon, H. & Bukkapatnam, S. Crafting large prototypes. IEEE Robot. Autom. Mag. 8, 33–42 (2001).

Lim, S. et al. Developments in construction-scale additive manufacturing processes. Autom. Constr. 21, 262–268 (2012).

Xu, W. et al. Toward automated construction: the design-to-printing workflow for a robotic in-situ 3D printed house. Case Stud. Constr. Mater. 17, e01442 (2022).

Gaudillière, N. et al. in Robotic Fabrication in Architecture, Art and Design 2018: Foreword by Sigrid Brell-Çokcan and Johannes Braumann, Association for Robots in Architecture 459–472 (Springer, 2019).

Ma, Y. & Che, Y. A brief introduction to 3D printing technology. in 17th International Congress of the GRCA (GRCA, 2015).

Bos, F. P. et al. The realities of additively manufactured concrete structures in practice. Cem. Concr. Res. 156, 106746 (2022).

Wilson, T. T., Mativenga, P. T. & Marnewick, A. L. Sustainability of 3D printing in infrastructure development. Procedia CIRP 120, 195–200 (2023).

Jo, J. H., Jo, B. W., Cho, W. & Kim, J.-H. Development of a 3D printer for concrete structures: laboratory testing of cementitious materials. Int. J. Concr. Struct. Mater. 14, 1–11 (2020).

du Plessis, A. et al. Biomimicry for 3D concrete printing: a review and perspective. Addit. Manuf. 38, 101823 (2021).

Liu, J., Li, S., Fox, K. & Tran, P. 3D concrete printing of bioinspired Bouligand structure: a study on impact resistance. Addit. Manuf. 50, 102544 (2022).

Wu, Z., Pan, H., Huang, P., Tang, J. & She, W. Biomimetic mechanical robust cement-resin composites with machine learning-assisted gradient hierarchical structures. Adv. Mater. 36, 2405183 (2024).

Siddique, S. H., Hazell, P. J., Wang, H., Escobedo, J. P. & Ameri, A. A. H. Lessons from nature: 3D printed bio-inspired porous structures for impact energy absorption — a review. Addit. Manuf. 58, 103051 (2022).

Brown, K. A. & Gu, G. X. Computational challenges in additive manufacturing for metamaterials design. Nat. Comput. Sci. 4, 553–555 (2024).

Du, G., Sun, Y. & Qian, Y. Flexural performance of nature-inspired 3D-printed strain-hardening cementitious composites (3DP-SHCC) with Bouligand structures. Cem. Concr. Compos. 149, 105494 (2024).

Houshmand Khaneghahi, M. et al. Development of a nature-inspired polymeric fiber (BioFiber) for advanced delivery of self-healing agents into concrete. Constr. Build. Mater. 408, 133765 (2023).

Zhang, T. et al. Development of a novel bio-inspired cement-based composite material to improve the fire resistance of engineering structures. Constr. Build. Mater. 225, 99–111 (2019).

Li, Q. et al. A novel bio-inspired bone-mimic self-healing cement paste based on hydroxyapatite formation. Cem. Concr. Compos. 104, 103357 (2019).

Ahamed, M. K., Wang, H. & Hazell, P. J. From biology to biomimicry: using nature to build better structures — a review. Constr. Build. Mater. 320, 126195 (2022).

Zhang, F. et al. Unperceivable motion mimicking hygroscopic geometric reshaping of pine cones. Nat. Mater. 21, 1357–1365 (2022).

Del Dottore, E., Mondini, A., Rowe, N. & Mazzolai, B. A growing soft robot with climbing plant-inspired adaptive behaviors for navigation in unstructured environments. Sci. Robot. 9, eadi5908 (2024).

Bandyopadhyay, A., Traxel, K. D. & Bose, S. Nature-inspired materials and structures using 3D printing. Mater. Sci. Eng. R Rep. 145, 100609 (2021).

Cohen, Z. & Carlson, N. Piling and pressing: towards a method of 3D printing reinforced concrete columns. Constr. Robot. 4, 61–73 (2020).

Acknowledgements

The authors appreciate the financial support from the Hong Kong Research Grants Council (RIF R6008-24 and HKUST 15231522) and HKUST ‘30 for 30’ Global Talent Acquisition Campaign.

Author information

Authors and Affiliations

Contributions

Yuying Zhang and X.Z. contributed equally to all aspects of the article. M.L. and C.Z. researched data for the article. Yamei Zhang, X.D., N.B., V.M., J.V.C., P.J.M.M. and D.C.W.T. contributed substantially to the discussion of the content and revisions of the article. Yuying Zhang, X.Z., M.L., C.Z. and D.C.W.T. reviewed and edited the manuscript before submission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Clean Technology thanks M. Kan; H. Zhou, who co-reviewed with P. Zandifaez; and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Zhu, X., Li, M. et al. 3D printing technology in concrete construction. Nat. Rev. Clean Technol. 1, 288–303 (2025). https://doi.org/10.1038/s44359-025-00047-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44359-025-00047-z

This article is cited by

-

From printing to performance: a review on 3D concrete printing processes, materials, and life cycle assessment

Journal of Building Pathology and Rehabilitation (2025)