Production rates improve 50% in some cases

Justin Pizzitola

Oceaneering International, Inc.

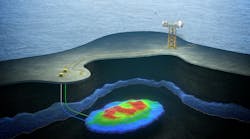

Deepwater operators can have more flexibility insubsea well interventions by employing a stimulation method that does not require a drilling rig and conventional riser. This approach includes the use of a multi-purpose service vessel (MSV), dual open water coiled tubing riser units, and a well stimulation tool (WST) for access into a reservoir.

Presented here are factors that operators should consider when planning an intervention using this method. Also, the importance of planning and project management is emphasized in order to perform rigless interventions safely and successfully.

Rig operations

Production from subsea wells can be impaired over time by fines migration from materials including paraffins, asphaltenes, and scale. These problems can occur even in wells that have permanent systems to inject chemicals to control particles and deposits. At some point, intervention is usually required to restore production, typically by pumping treatment chemicals into the well.

The most common method for subsea well intervention involves using a mobile offshore drilling unit and a stimulation vessel, along with a drilling riser and blowout preventer (BOP) placed on top of the wellhead. Because of the major assets required, the large crews needed for the operation, and the time-consuming operations of rig-up and rig-down, a single well deepwater intervention can take a week or longer to complete.

Oceaneering has developed a method to restore production within a significantly reduced amount of time, with simpler logistics, and without compromising safety or well control.

Rigless intervention

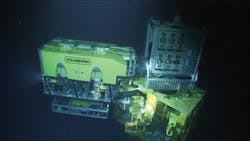

This alternative intervention method uses an MSV to safely perform well stimulations without a drilling rig, riser, or BOP. With this approach, the vessel carries two work-class remotely operated vehicles (ROV) and is fitted with a crane to lower equipment to the seafloor. The rigless intervention process is performed using both ROVs, dual open water coiled tubing riser units, flying leads, high-pressure pumps, and associated piping. In addition, a WST provides the main interface between the topsides and the well tree. Rig-up and testing can be completed in two days, compared to a week or more for rig-based well intervention.

In addition to the ROVs and other equipment, the MSV can carry up to 5,000 bbl of pre-mixed treatment chemicals. If a larger volume is required, bulk chemicals can be mixed on the fly, or a stimulation vessel can be used for the high- or low-pressure transfer of fluids to eliminate additional trips to shore.

The MSV stimulation method can treat wells at pumping rates up to 20 bpm and 15,000 psi using dual open water coiled tubing riser units and a WST, which assures safe operation by providing a double barrier for well control. Two “fail-close” valves can be actuated from the surface and automatically closed if unexpected events are occur/transpire. An emergency quick disconnect system (EQD) enables the vessel to disengage from the well with zero leakage in the event of mechanical problems or loss of vessel dynamic positioning control. An additional EQD system is installed between the MSV and stimulation vessel when operating in a dual-vessel configuration.

Additionally, the subsea tree is powered and controlled from the vessel through an umbilical instead of relying on the host facility. While the stimulation is performed, real-time data including topsides pump pressures and flows, and subsea pressures at the tree interface, plus video from ROVs, can be delivered back to shore.

Factors for consideration

Operating company production engineers should consider several factors when planning a subsea intervention using an MSV. First, produced fluids should be analyzed to determine the cause of the blockage and choose the appropriate treatment chemicals. Reservoir characteristics should also be reviewed to characterize the formation’s injectivity and determine optimum pumping rates.

Also, operators need to determine the best method to access the wellbore for the intervention. There are several options for landing out the WST for wellbore access, including latching onto the tree hub directly, locking onto a nearby suction pile, or deploying the WST with its own mud mat. For vertical trees, the WST can be latched to the tree hub and gain through bore access to the wellbore. Wellbore access can be obtained using flying leads from the WST over to a choke insert equipped with a high-flow access point for the other land out methods.

Effective project management is critical to integrating all technologies, and both in-house and third-party services are needed to perform subsea well stimulation. Detailed planning includes developing a robust front-end engineering and design study, a detailed safety plan including HazIDs, and an operability matrix to integrate operations for each project and assure continuous pumping while anticipating weather and ocean conditions.

GoM projects

A subsea well in theGulf of Mexico’s Mississippi Canyon area experienced a significant drop in production due to fines migration, which caused formation impairment. The operator decided that an acid stimulation was needed to restore production.

Oceaneering proposed a rigless operation using a WST to bullhead the planned chemical treatment into the well and the reservoir at 11,000 psi. An MSV equipped with skid-based stimulation pumps and carrying tanks above and below deck, transporting acid, solvents, and nitrogen carried out the intervention. In addition to the WST, equipment included dual open water coiled tubing riser units, nitrogen pumps, a 10,000 psi tree running tool with adapter, and a neutralization tank with gas buster.

The company also contracted and managed all third-party suppliers, working with DNV GL USA to obtain approval for the fire and safety plan, piping and instrumentation, and chemical carrying and handling procedures.

The rigless stimulation pumped 1,100 bbl of acid into the well during three days of pumping. The operation was completed for $15 million less than a rig-based stimulation, and the well’s productivity improved by 75%.

Another operator in the Gulf of Mexico determined that production from two wells in 4,300 ft (1,310 m) of water had been impaired due to particle accumulation. Production engineers decided that each well needed a treatment schedule that had to be pumped within a 15-hour time window. In addition, the volumes required would exceed the MSV’s capacity using pre-mixed chemicals.

After detailed planning, the project team designed a treatment that would enable bulk chemicals to be mixed on the fly and injected into the wells from the MSV. Using this approach, pre-mixed chemical volumes stored on the vessel could be reduced significantly, enabling a single vessel to carry out the stimulation.

The project was scheduled during winter in potentially difficult weather. An operability matrix was prepared – with close attention to weather, current, and sea states – to allow for a 24-hour pumping window to meet the required 12-15 hour pumping schedule.

The MSV was mobilized with nitrogen, nitrogen pumps, dual open water coiled tubing riser units, mixing units, metering equipment, and 2,500 bbl of bulk chemicals. All treatment fluids were mixed on the fly and pumped according to schedule, and each well was stimulated successfully.

West Africa project

Offshore West Africa, an operator planned to stimulate five wells in 4,420 ft (1,347 m) of water, whose production had dropped because of the accumulation of fines, calcium carbonate, and scale.

To cost-effectively stimulate the five wells 60 mi (97 km) offshore, Oceaneering designed a dual-vessel plan to be implemented using an MSV and a stimulation vessel. The MSV deployed four open water coiled tubing units, two work-class ROVs, and a modified WST. The stimulation vessel carried the needed treatment fluid volume and provided pumping services. During well intervention, this vessel pumped chemicals through a high-pressure hose to the MSV, down to the WST, and into the wellhead.

To assure safe spacing between the MSV and the stimulation vessel, transponder frequencies for the dynamic positioning systems on the two vessels – and other vessels close to the operation – were managed by the field mooring master. In addition, the MSV used a long baseline acoustic array to maintain its position in relation to the subsea assets, and the stimulation vessel employed a fan beam configuration to to maintain an adequate distance from the MSV.

To achieve the maximum required pumping rate of 16 bpm, the WST was modified to accommodate four open water coiled tubing riser units. This change doubled the achievable flow rates, enabling optimal treatment for each well’s unique characteristics. To prevent leaks and avoid safety or environmental impacts, coiled tubing connections to the WST were made using proprietary ejectable hot stabs, which also reduced tool costs and simplified ROV operations.

The dual-vessel approach successfully injected an average of 1,370 bbl of treatment chemicals into each of the five wells, achieving impressive gains in production. The average well experienced a 350% surge in its productivity index and a production rate increase of more than 70%.

Since 2007, the rigless approach to subsea well stimulations has been used on more than 30 deepwater interventions, improving production by an average of more than 50%. Additional deepwater rigless stimulation projects are scheduled through the end of the year.