CombiPolish® Wins Innovation Award

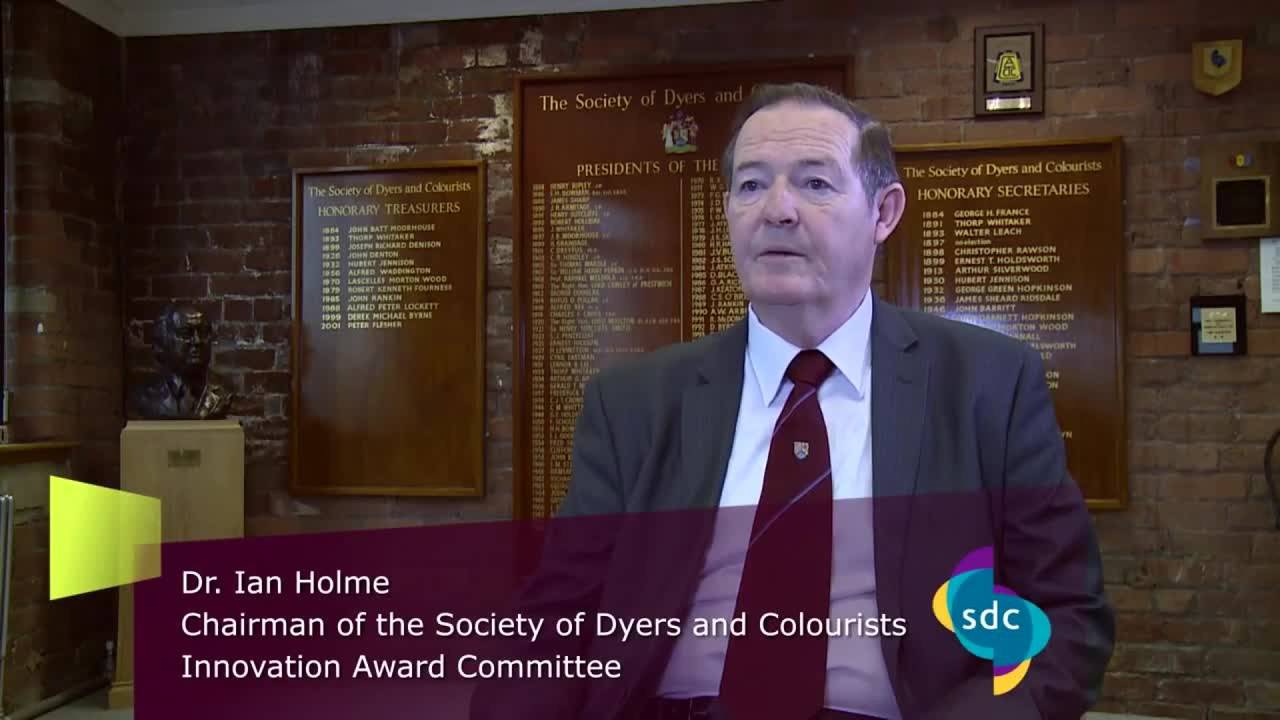

”This award is given to companies who have reached the pinnacle of achievement in textile dyeing and finishing” says Dr. Ian Holme, the chairman of the Society of Dyers and Colourists Innovations Award committee.

”This award is given to companies who have reached the pinnacle of achievement in textile dyeing and finishing” says Dr. Ian Holme, the chairman of the Society of Dyers and Colourists Innovations Award committee.

Our biopolishing solution is the basis of the new technology that one of England’s leading retailers is using to promote their long-lasting school cardigans.

The microfibrils that protrude from cellulose-based fibers cause fuzz and pilling. They also trap dirt and obscure colors. By breaking down microfibrils, cellulases prevent these effects.

Textile mills biopolish cellulose-based fabrics before, during or after dyeing. The process improves the surface softness, cleanness and brightness of a range of fabrics. These include cotton, viscose, lyocell and modal.

Microfibrils are microscopic hairs that protrude from the fibers of these fabrics. They lead to fuzz and pilling, which makes the fabric surface feel rough. They also trap dirt to reduce cleanness. Both the trapped dirt and the microfibrils themselves make colors and whites look less bright.

The cellulose molecules that form the fibers of these fabrics consist of long glucose chains. It's thought that biopolishing cellulases specifically target and cut protruding microfibrils into smaller sugars. This makes them easier to lift away from the fabric. The result is softer, cleaner and brighter fabrics with less fuzz and improved pilling notes.

Explore our product families for biopolishing below. To find out more about our biopolishing range, get in touch with your local Novozymes representative.