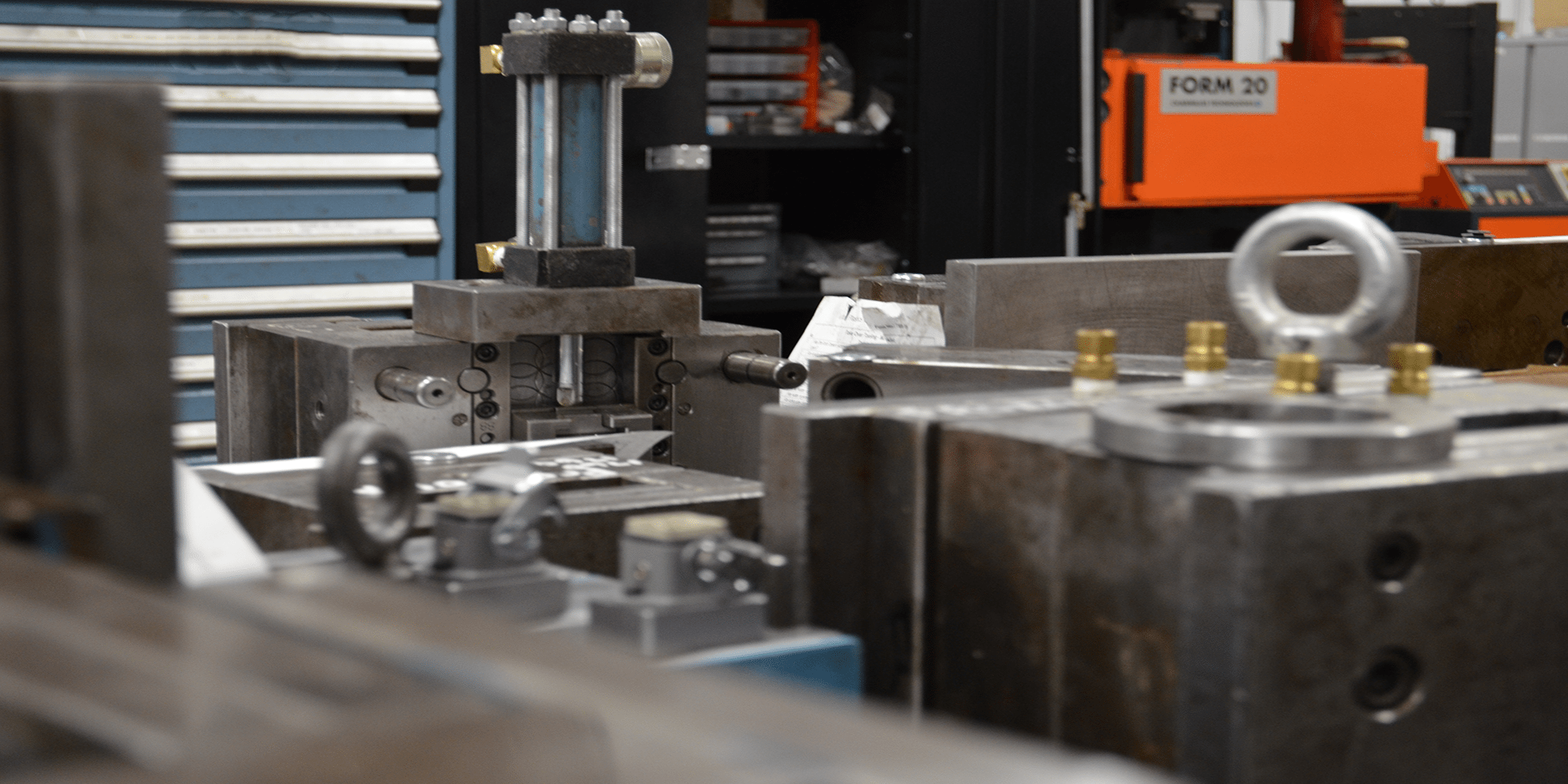

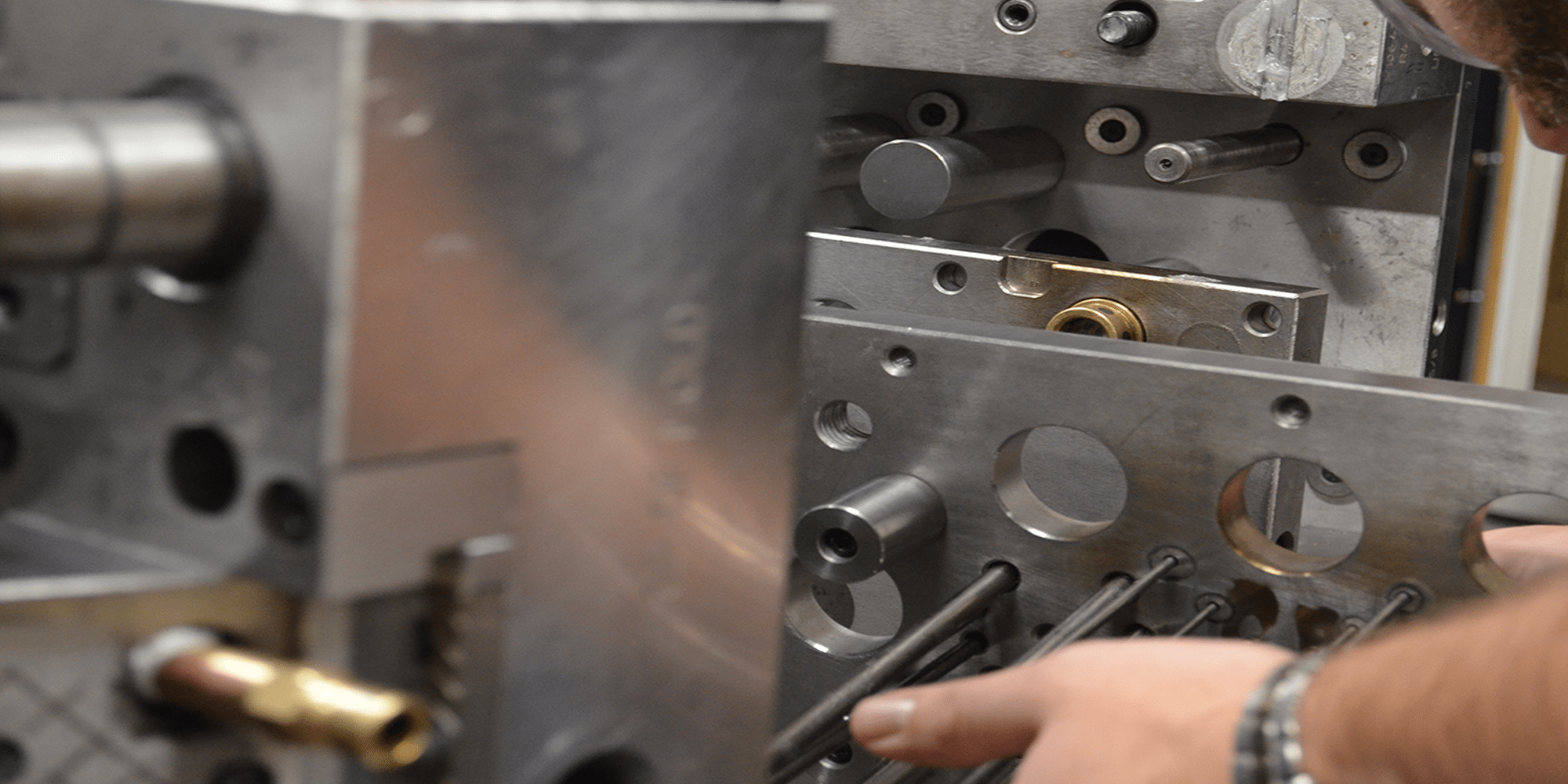

Plastic Injection Molds: In-House

From the initial design stages through production and tooling maintenance, your plastic injection molds quality is our top priority. Our ERP driven, automatic PM(Preventative Maintenance) scheduling on all tooling and equipment takes out the guess work of when tools should be scheduled for maintenance. Utilizing our dry-ice blaster and ultra-sonic baths for your mold cleaning, we ensure that the tools are ready for production at a moments notice. With our in-house tooling capabilities and outside partnerships, Vital Plastics has the ability to not only build you prototype or production tooling, but we also create all of the custom fixtures and jigs needed.

Domestic Tooling

Off-Shore Tooling

Complex DFM Analysis on All New Projects

ERP Driven PM Schedule

Comprehensive Tool Design Review

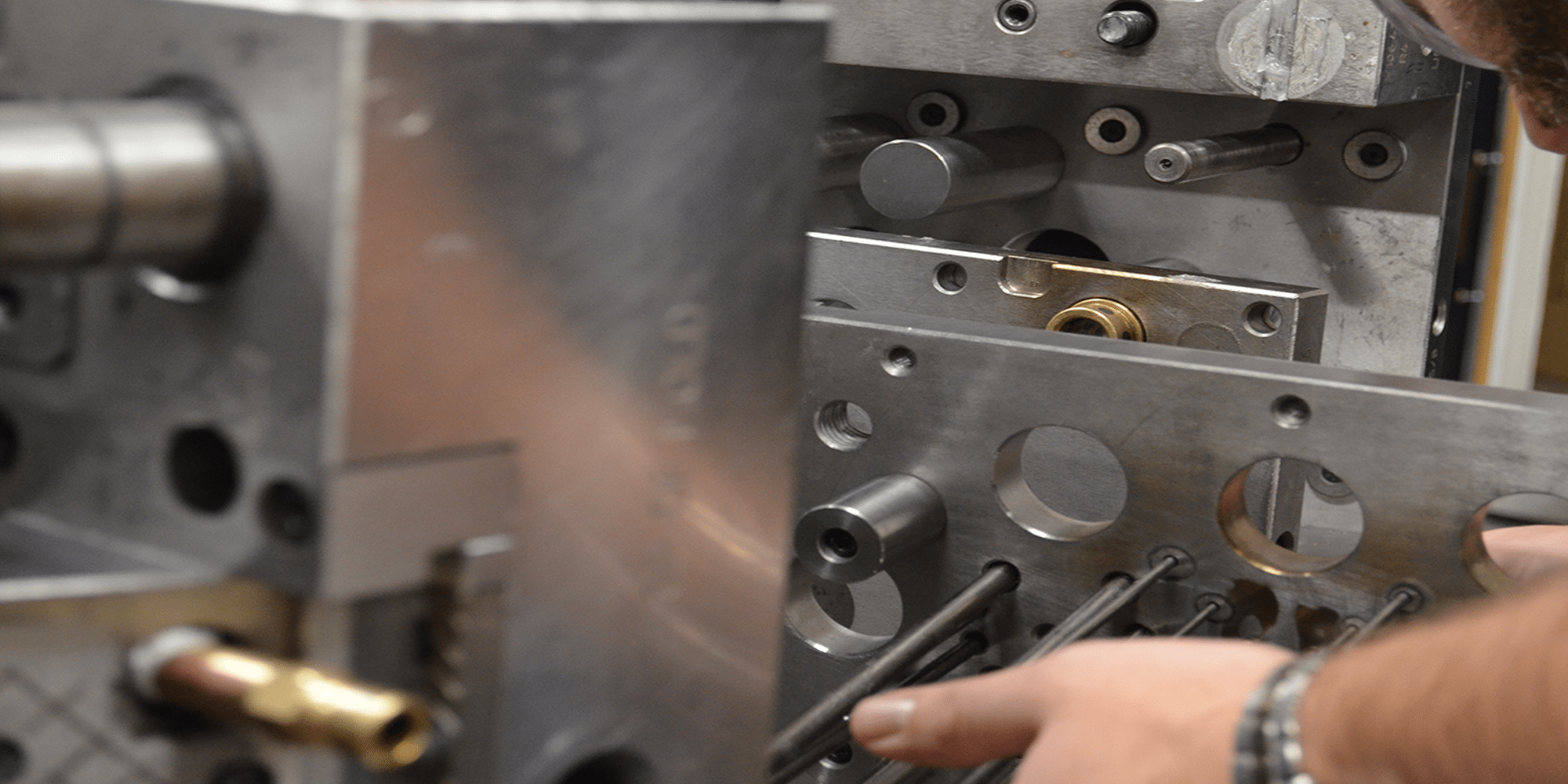

Vital Tooling Solutions

We take careful measures and the required steps to ensure your tooling produces the highest-quality components while maximizing the life of the tool. Our tooling department gives us the capabilities to optimize your molded components and maximize the life of your plastic injection molds.

Automatic Tool Maintenance Schedule

Tool Modifications and Rev Changes

Aluminum and P-20 Prototype Tools

Production Tools: P-20, 420SS, H13, Etc.

Complex Slides and Side Actions

Hydraulic and Pneumatic Core Pulls

Hot Tips, Valve Gates, Sub-Gates, Cold Runners

Insert Molding & In-Mold Decorating

Integration With Your Manufacturing

Through Engineering, Collaboration & Innovation

Prototype & Production

From simple open and close prototype tools through complex multi-action H-13 production tools, Vital Plastics has the technology and expertise to assist with any type of tooling projects. Our tooling department also manages all of our internal jigs & fixtures as well as any type of automation that is required either at the press or in secondary assembly operations.

The Vital Differences

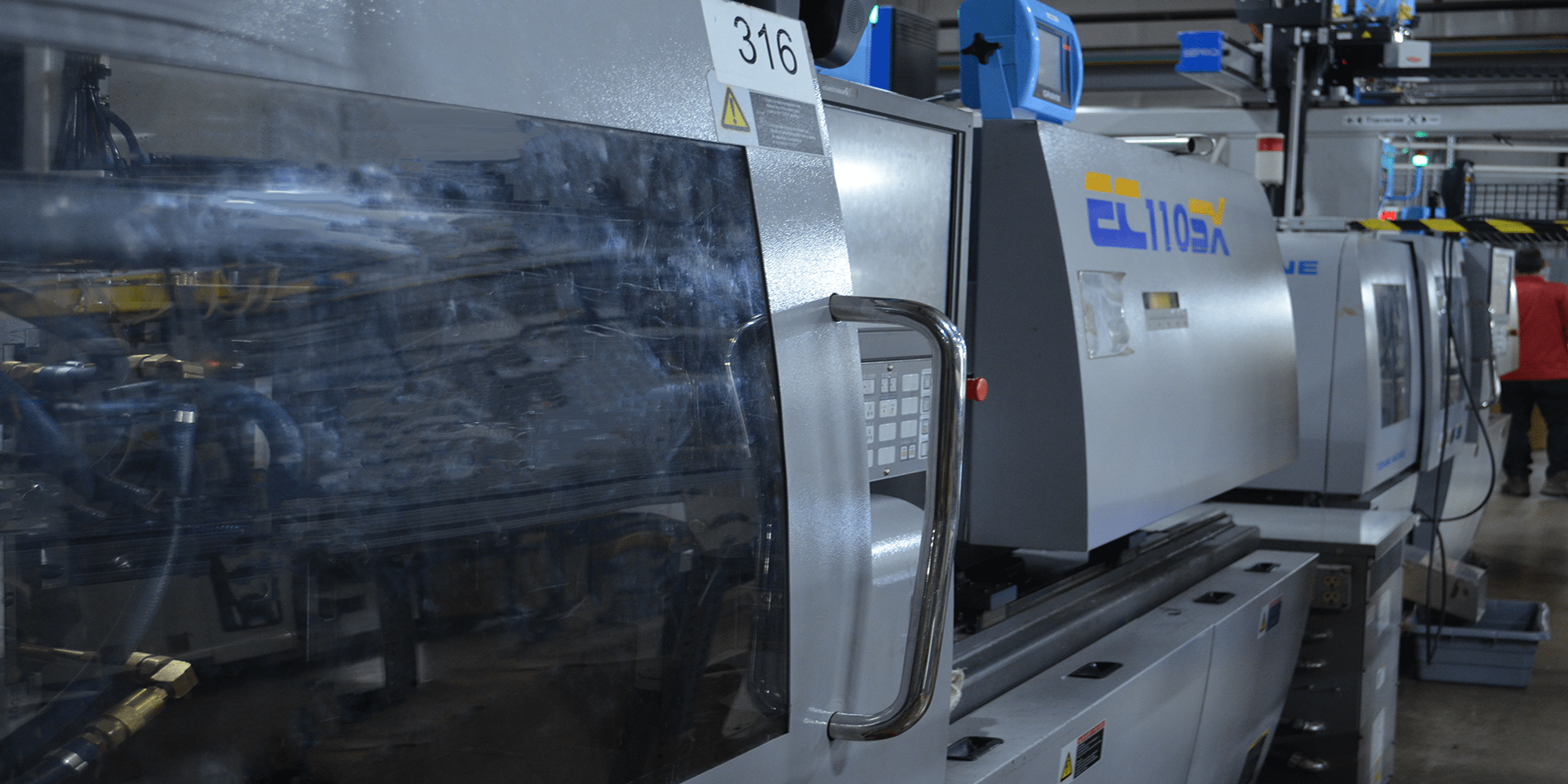

INJECTION MOLDING

With Over 56 injection molding machines ranging from 30 Tons – 400 Tons, Vital Plastics has the capabilities, engineering resources, and technology to become your premier supply-chain partner.

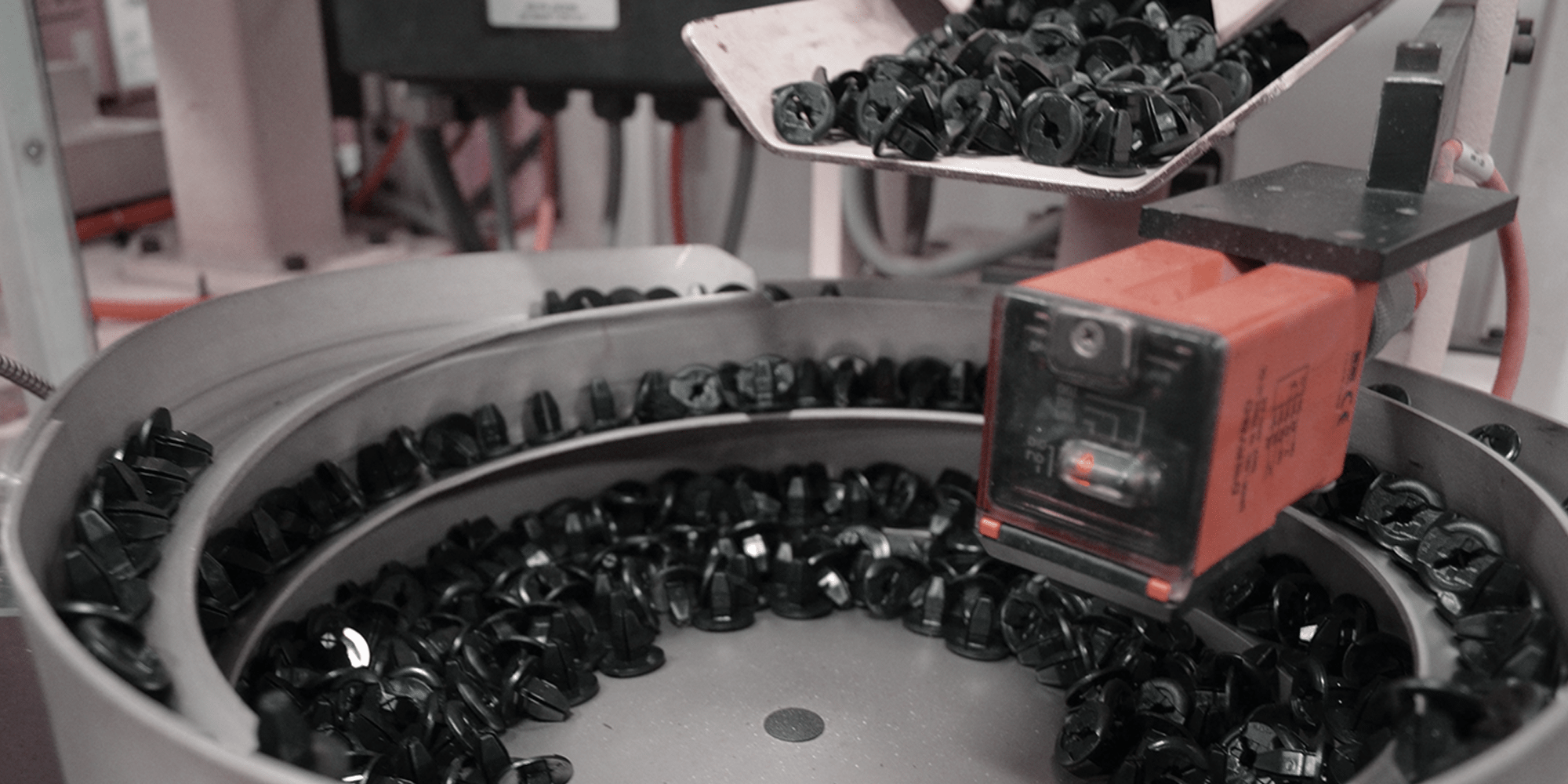

ASSEMBLY OPERATIONS

We focus on providing the most comprehensive post-molding & value-added services available to our customers. Whether it’s a fully-automated, semi-automated or hand assembly/kitting, we are dedicated to providing our customers with more than just injection molding capabilities.

TOOLING SOLUTIONS

From simple rev changes to new tooling projects, we have the capabilities and resources to handle the most complex injection molded parts. Additionally, our off-shore partnerships can provide cost effective tooling solutions, depending on the project.

SUPPLY-CHAIN SOLUTIONS

Looking for a new Partner? Look no Further!