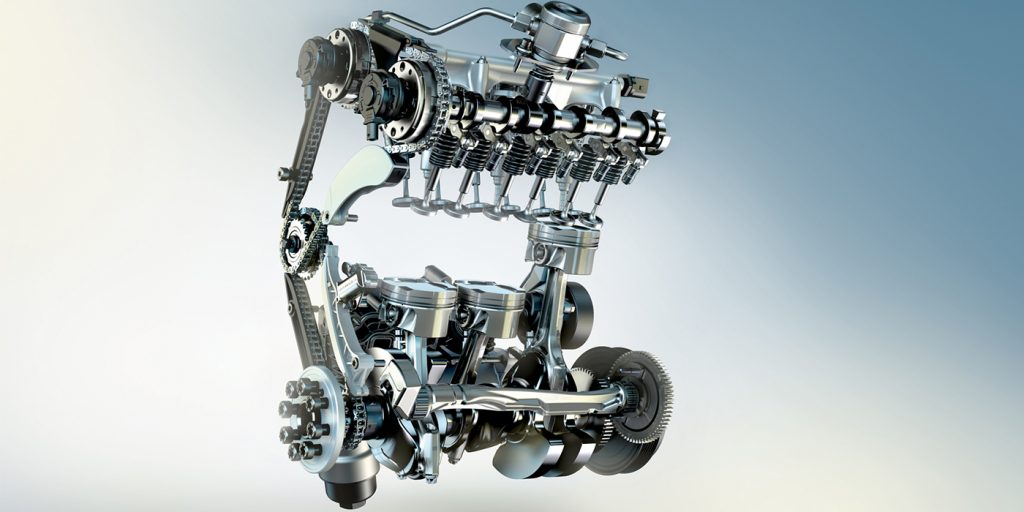

When most BMW owners hear the phrase “timing chain stretch,” they assume that the gears on the crankshaft and camshaft sprockets have pulled on the chain, causing the links to lengthen like a rubber band. It is not that dramatic. Over the past decade, BMW and many other import automakers have had issues with timing chain stretch.

What’s happening is the holes in the links for the pins that were round are wearing into ovals. The change in the shape of the holes causes the distance between the pins to increase by a few microns for eack link. But, timing chains have many links that turn microns into millimeters.

The most common cause of timing chain stretch is lack of maintenance and regular oil changes. Worn out oil can no longer lubricate the chain and will cause the rollers and links to wear against each other. As the chain runs around the gears of the camshafts and crankshaft, the movement between the rollers and links causes wear and elongation.

As the timing chain wears, this can change the timing of the camshaft and crankshaft. The change in timing is sensed by the camshaft and crankshaft position sensors, which can cause codes that indicate the correlation or synchronization problem with the engine position sensors.

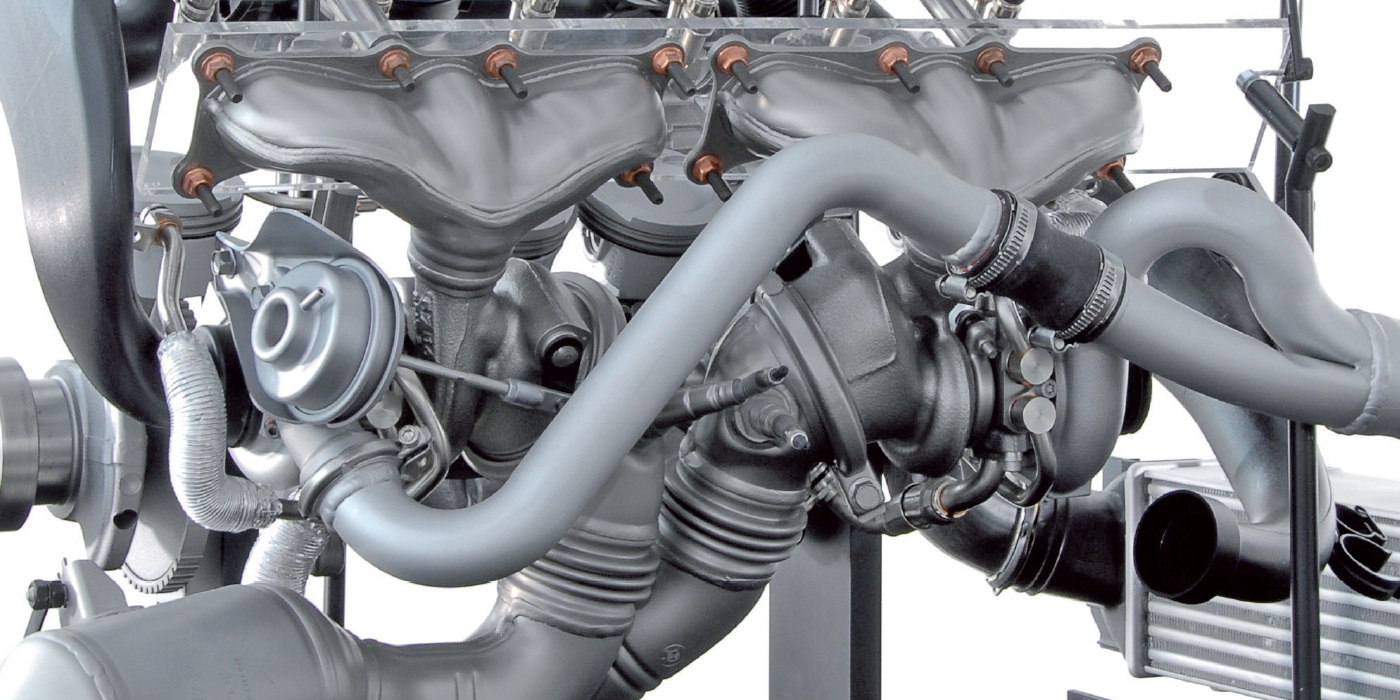

The wear to the links can be increased if the tensioner or guides are not able to control the movement of the chain. In rare cases, the timing chain may have been made from inferior metals. But, the most likely cause is missed oil changes and using oil that is not approved for the engine.

If the driver ignores the check engine light, eventually the timing chain will elongate to the point that the engine may have a significant loss of power due to a lack of compression. In some cases, a worn timing chain may cause the engine to jump time a few teeth. If this happens on a multi-cam engine it may appear to be a dead miss on multiple cylinders. The bad oil can also damage the tensioner, which makes the possibility of the engine skipping time or a catastrophic failure even greater.

If you are replacing a timing chain or chains, it is also critical to inspect and, in some cases, replace components that tension the chain and variable valve timing actuators. The actuators are powered by the same oil that damaged the timing chain. Inside a variable valve timing actuator are finely machined surfaces and seals that can easily be damaged by worn out or improper oil. In some cases, it is cheap insurance to replace the actuators while you are replacing the timing chain to ensure that the customer gets the full value of the labor time.

If you are trying to diagnose timing chain stretch, it might be impossible to access the timing mark without major disassembly. The easiest way to check timing is to use a scope to capture the waveforms of the crankshaft and camshaft position sensors.

Timing chain replacement can be very expensive. Some owners believe it is a warranty issue with the manufacturer. But, the real issue and cause of the stretch might be an owner stretching a dollar when it comes to oil changes.

Article courtesy ImportCar.