If you’ve ever wondered what’s in a bottle of fuel-system cleaner and whether or not it does what it says it does, you’re not alone.

The fact is, most engines with fewer than 100,000 miles probably don’t need any help cleaning the fuel system, since top-tier gas stations use many additives in their fuel – including ethanol – to maintain a clean environment for the fuel to run through.

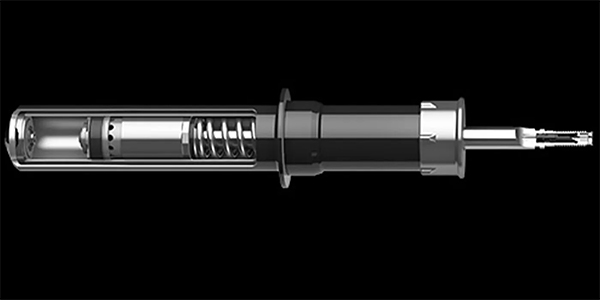

Fuel injectors are computer-controlled to deliver precisely the right amount of gasoline to the combustion chamber for the driving situation (i.e., load, no load, etc.). A gummed-up or clogged fuel injector can cause hard starts, power loss, rough idling, reduced fuel economy and increased emissions.

When poor-quality gasoline is used, it can cause deposit buildup, misfires and hot spots in the combustion chamber. Over time, it can lead to a loss of power. Smaller, turbocharged engines are extra-sensitive to deposits that build up on fuel injectors and intake valves and in combustion chambers. Even small amounts of buildup can increase exhaust emissions, reduce fuel economy and cause drivability problems and engine knock.

The EPA’s minimum detergency standard is known as the Lowest Additive Concentration (LAC) and is designed to help control exhaust emissions. But the minimum requirements might not be enough in some cases. Several companies use additives that feature higher concentrations of cleaning agents. However, a large percentage of gasoline sold in the United States is at LAC levels, meaning vehicle owners might need the help of a fuel cleaner, or they might consider running top-tier gasoline at all times.

Consumer Reports conducted a test of top-tier vs. regular gasoline and concluded that, on average, top-tier gasoline had fewer carbon deposits on injectors, intake valves and in the combustion chamber when compared to regular gas, by as much as 19 times less. The report said that for the money, top-tier fuel is worth the investment.

Fuel injectors can be cleaned using a detergent called polyisobutylene amine (PIBA) if it’s a port fuel-injected engine. However, if the engine is direct-injected, as millions of late-model engines are, it’s more difficult to clean. Gasoline direct-injection (GDI) engines require a stronger additive called polyether amine (PEA), to survive the heat of a combustion chamber where the injector tip is exposed.

Using a fuel additive that contains PEA can help restore the engine’s fuel efficiency and improve performance in as little as one use. PEA scavenges water and helps neutralize the corrosive effects of ethanol blends. Manufacturers of additives with PEA say continued use of these products will give you even better results. But, the big question is IF the engine was contaminated enough in the first place. The Federal Trade Commission warns consumers to beware of products that make exaggerated claims, and says in all of its lab tests the agency has never seen any product or device that significantly improves fuel economy.

When to Use a Fuel Additive

Overall, using a fuel additive can be a good idea if your customer has an older vehicle or regularly fills up with discount gas. Fuel cleaners with quality additives can improve combustion, enabling engines to start easier and run smoother. Burning fuel more completely also helps to lower emissions and reduce carbon deposits. If the deposits are left untreated, the condition will affect the performance and fuel economy of the vehicle.

With more GDI engines on the road and low-priced gas distributors on just about every corner, you can keep customers happy – and add a little to the bottom line – by selling them a quality fuel additive.