No matter how complicated and how well-designed your robots are, they're only as good as what's inside them. Batteries, sensors, motors, but most importantly gears, and it's gears where NASA is throwing a ton of it brainpower. After all, if the gears break, what good is anything else?

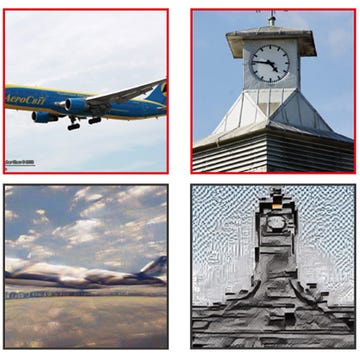

The bulk of the research is being performed at NASA's Jet Propulsion Laboratory in Pasadena, California, and its focus isn't so much on changing the way gears typically work; don't expect any weird new shapes or strange new rotary transmission designs. Instead, the plan is to work on the materials, specifically to come up with something that can handle the frigid void or even icy planets without becoming so brittle that it's at risk of shattering.

The most promising candidate is a material that's both metal and yet also glass. The trick to producing this "metallic glass" is to take metal and heat it up to the temperature at which its typically crystalline atomic structure gives way to something more fluid. In other words, until it melts. If allowed to cool naturally, the metal will revert to its original atomic state, but if frozen quickly, you can get the best of both worlds. That is, these metallic glasses can be easily melted and formed into gears, but are incredibly strong and don't get brittle at low temperatures.

Metallic glasses were first discovered in the early 1960s when CalTech researchers experimented with cooling a molten gold-silicon alloy at speeds of nearly 1.8 million degrees Fahrenheit (one megakelvin) per second. The latest innovations in Pasadena rely on roughly the same principle, but is dubbed "bulk" metallic glass due to the quantity that can be created at once.

Right now, the idea application for this tech is space, but it could trickle down to more Earthly pursuits over the years, as so much NASA tech has. Bulk metallic glass could make it much cheaper to build "strain wave" gears, which make use of a flexing metal ring and tend to be prohibitively expensive.

According to technologist Douglas Hofmann, who's working on the project:

Mass producing strain wave gears using BMGs may have a major impact on the consumer robotics market. This is especially true for humanoid robots, where gears in the joints can be very expensive but are required to prevent shaking arms. The performance at low temperatures for JPL spacecraft and rovers seems to be a happy added benefit.

And if someone can use this same tech to make something wacky and useless too, that's fine by us.

Source: NASA