Junkosha Liner Tubing

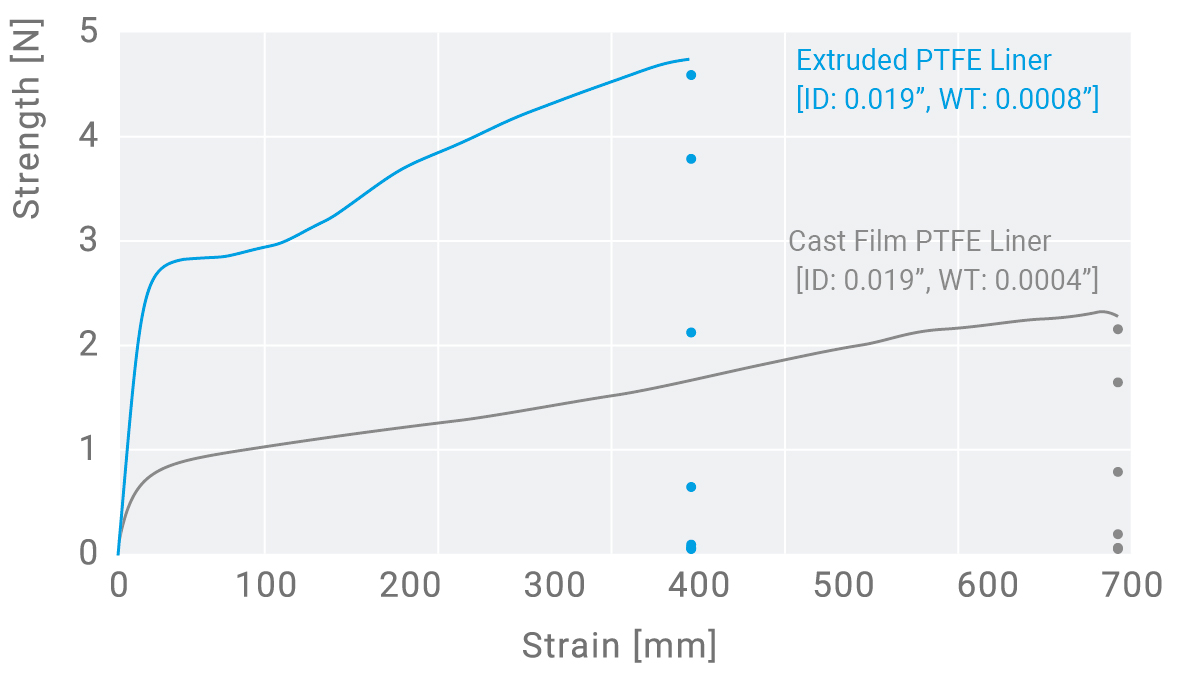

The superior lubricious properties of PTFE make it an excellent material choice for lining catheter lumens. Conventional dip-coated or film cast PTFE Liners are mechanically weak, exhibit low tensile strength and are prone to inconsistencies. Junkosha PTFE Liners are robust, high in tensile strength, have superior consistency in elongation and elastic properties, and are available with ultra thin walls to meet critical catheter dimension requirements. Junkosha PTFE Liners are available with optimized etching and surface treatment to enhance reflow and adhesion even in the most demanding tapered catheter designs.

Features

- High tensile strength and consistent elongation (stretch control) resulting in higher yield rates during lamination

- Higher tensile strength/more consistent stretching prevents inserted/delivered devices from becoming stuck inside catheter shafts

- Improved abrasion and scratch/tear resistance compared to dip-coated or film cast PTFE Liners

- Custom sizes available with Inner Diameters from 0.012” up to 0.130” (0.30mm – 3.3mm) and wall thicknesses from 0.00075” to 0.002” (19µm to 50µm)

- Outer surface treatment available (etching)

- Meets USP class VI plastics standards

- Higher tensile strength/more consistent stretching prevents inserted/delivered devices from becoming stuck inside catheter shafts

- Improved abrasion and scratch/tear resistance compared to dip-coated or film cast PTFE Liners

- Custom sizes available with Inner Diameters from 0.012” up to 0.130” (0.30mm – 3.3mm) and wall thicknesses from 0.00075” to 0.002” (19µm to 50µm)

- Outer surface treatment available (etching)

- Meets USP class VI plastics standards

Use

- Micro-catheter inner liner for embolization coil delivery

- Inner liner for transcatheter delivery of stent graphs or heart valves

- Inner liner of lumen for control wire of steerable catheter

- Inner lumen for guidewire port of rapid exchange catheter

- Inner liner for transcatheter delivery of stent graphs or heart valves

- Inner liner of lumen for control wire of steerable catheter

- Inner lumen for guidewire port of rapid exchange catheter

| EPL | |

| Material | PTFE |

| Inner Diameter (inch) | 0.012~0.130 |

| Inner Diameter (mm) | 0.30~3.3 |

| Wall Thickness (inch) | 0.00075~0.002 |

| Wall Thickness (㎛) | 19~50 |

| Biocompatibility | USP class Ⅵ plastics |

Tensile Strength Test

- Junkosha Extruded PTFE Liner’s Ability to withstand Stress against Strain

Related Products

- Search for products that interest you

-