Frequently Asked Questions

If you have a question that is not listed below, please get in touch.

What are the basic differences between large lithium based batteries and vanadium flow batteries?

The vanadium flow battery (VFB) uses a different method of storing energy than Li-ion batteries.

VFBs use a circulating electrolyte solution of vanadium pentoxide to store the charge in tanks, while Li-ion batteries store all the charge inside the battery cell itself. VFBs have lower energy density compared to Li-ion, but since the tanks can be scaled up to any size, have the ability to store a lot more total energy. Li-ion batteries are able to deliver very high power quickly, hence are very suitable for mobile applications such as electric vehicles.

VFBs are energy batteries and therefore very suitable for storing large amounts of energy (particularly renewable energy) for later use. Because flow batteries can cycle more often and to greater depths of discharge (100%), they have a longer life than Li-ion batteries which eventually become less efficient when cycled too frequently.

Inherently, vanadium flow batteries are safer than Li-ion since they are not prone to the thermal runaway known to occur with Li-ion batteries.

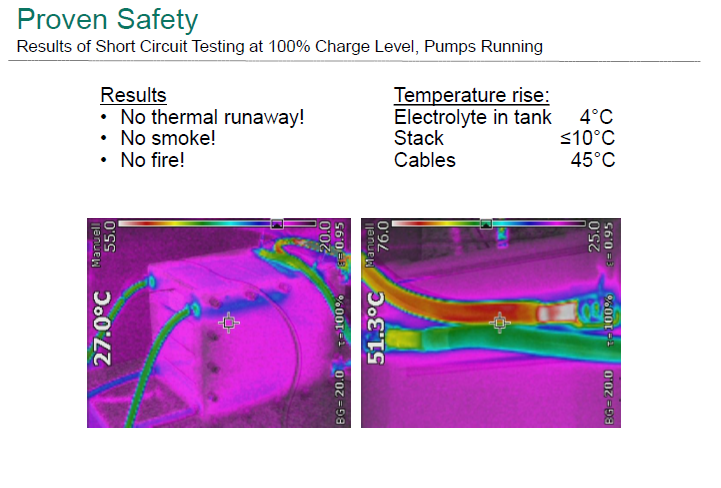

Deliberate stack (contains 20 cells) short circuit testing shows no signs of failure or catastrophic temperature rise:

How much does a vanadium flow battery cost?

Each requirement for energy storage is different and the solution is therefore tailored to the particular client. When we can see that our products offer the right solution for a client, we can then provide a quote.

Some clients require a battery to store energy from existing renewable energy generation, some require a solution which includes generation, others want to charge the battery using off-peak standard power. We have on-grid and off-grid solutions and there are many variables. We are happy to discuss individual requirements to see if we have a solution that is appropriate.

Please get in touch to find out more.

How far advanced is development of the vanadium flow batteries?

VFBs are commercially available. The technology was invented at the University of New South Wales in the 1980s and the university has a battery installed at its campus.

Companies worldwide have been implementing large-scale batteries for a number of years – Sumitomo for example has completed numerous installations, while the CellCube has over 100 installations worldwide.

Other manufacturers include Invinity Energy Systems, Rongke Power, VRB Energy, SCHMID and VFlow Tech. While in development for many years, VFBs have never before existed in a market with the current installed capacity and high demand for renewable energy as exists today.

Can the vanadium in the batteries be recycled?

The batteries have a life of 20+ years.

The electrolyte can be removed after this time and re-used in another battery or the V₂O₅ can be recovered for use in the steel industry. A truly sustainable solution.

Who is VSUN Energy partnering with in this strategy?

VSUN Energy is involved with a range of different stakeholders throughout the battery storage market. This includes battery makers, renewable installers and electrolyte producers.

- We sell batteries from a wide variety of manufacturers including Invinity Energy Systems, CellCube, Sumitomo and VFlow Tech.

- We are collaborating with US Vanadium on the development of vanadium electrolyte production capability in Australia in conjunction with Australian Vanadium Limited.

- We work closely with a variety of solar installers and have contacts in the wind industry.

The company is open to collaboration with all energy market participants.

Can the VFB be used in a microgrid or stand alone power system?

Yes, a microgrid or stand alone power system is a perfect setting for a VFB. Being able to offer many hours of energy with multiple cycles per day and a high heat tolerance make the VFB the perfect battery component of a microgrid or SPS.

How is VSUN Energy funded?

VSUN Energy is funded through ASX-listed company Australian Vanadium Limited (ASX: AVL). The company will actively assess other opportunities for future funding, but AVL is confident that shareholders will see the positive opportunity that exists in the energy storage market.

Do you provide a residential solution?

We are not able to provide a residential VFB at this time, however we are working with various manufacturers to try to get a suitable product for the Australian market.

In a multi-residential situation, we can offer a variety of solutions.

To keep up to date on this sector, please look out for releases by our listed parent company, Australian Vanadium Limited, (ASX: AVL) and via social media.

Is it environmentally sound to use a substance which has to be mined?

Vanadium, like copper, aluminium, iron and lithium, is a metal that mostly needs to be extracted from the earth’s crust by mining. All of these metals form part of everyday technology including batteries. Modern environmental laws in Australia demand that mining is conducted under strict conditions and within government regulations, to reduce environmental damage and ensure the rehabilitation of any land disturbed by mining. Vanadium, if used in a VFB in vanadium electrolyte, is anticipated to have a long life of up to 20 years in each battery system. If a battery system is de-commissioned for any reason, the vanadium solution and all the contained metal can be 100% reclaimed and re-used elsewhere.

VSUN Energy’s parent company AVL is planning to incorporate renewable energy, including VFBs, into the mine’s power supply. The company is also researching electric vehicles and hydrogen fuelled trucks. AVL is an active member of the Future Battery Industry Co-operative Research Centre (FBICRC) which provides a platform for collaboration with other mining companies to work together to drive forward the electrification of the mining industry.

An analysis of the Australian Vanadium Project’s carbon emissions from Scopes 1, 2 and 3 has demonstrated an annual carbon emission of -30 million tonnes – ie an overall reduction in emissions.

Can you explain some of the terminology used?

Cycling – cycling means charging and discharging the battery.

100% discharge capability means that the battery can be fully discharged to zero without damage.

Redox is an abbreviation where Red stands for reduction = gain of electrons, while Ox stands for oxidation = loss of electrons.

SOC – State of Charge

Cell – A closed electrochemical power source. The minimum unit of a battery. As an example, the CellCube FB10-100 has 10 modules of 20 cells plus 1 OCV cell for SOC measurement for a total of 201 cells. The Tesla Powerwall 85kWh has 16 modules of 444 cells for a total of 7,104 cells which all need to be monitored. Larger utility scale systems will also require cell voltage balancing, because when cells are in series, the performance of the overall system can be limited by the performance of the weakest cell. Source.

Cycle life – the number of charges and discharges a cell can perform before its capacity drops to 80% of its initial specified capacity. For a flow battery this is 20 years because the capacity loss is 1% per year or 10% over 10 years (this is where the 20 year lifetime number comes from).

Energy throughput – the total amount of energy in watthours (Wh) which can be taken out of a rechargeable battery over all the cycles in its lifetime before its capacity reduces to 80% of its initial capacity when new.

For a more comprehensive list of energy related meanings and acronyms, click here.