Celebration of Oscillation

„IN PRINCIPIO ERAT MENS“ – in the beginning was the idea

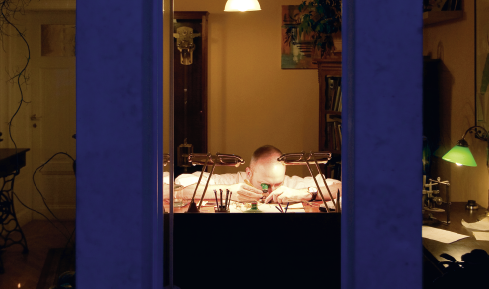

To create a masterpiece, you need the patience to dream and of course plenty of imagination. Most of my ideas I keep for many years in my head and like red wine they mature and become even better. When the time has come I take pencil and paper to organise my thoughts and ideas and create a concept for a watch.

For me designing a watch is like composing music. You start with all the different components, which are like the notes in music and gradually you build up to the dial and the movement and the case. Probably one year passes before I know all 200 parts will work together and the general idea of the watch is clear in my mind.

First comes, let’s say, the foundation of the movement, the plates and bridges. We do several test-millings with the CNC machine until we are satisfied with the raw bridges and plates. Depending on the caliber, the bridges and the plates will be engraved manually. They also receive a fine polishing and their edges are beveled. Before we do the gold plating the bridges and plates receive a coat of silver.

Through the time consuming process of silver grinding (rediscovered and enhances method used in the 19th century) we apply a mixture of salt and silver to the brass parts of the movement using a stiff-bristle brush. The result is a surface that has a grain like fine leather. The surface has brilliance and contrast called a frosted finish. You cannot achieve this with any other technology.

The flat parts like lever and springs will be milled from a glued steel plate. After tempering and measuring the parts it’s time for the main task of manufacturing: finishing. We carefully prepare all flat surfaces and all the edges then we bevel and polish them. All this will be done just as it was one hundred years ago. This is the reason the finishing takes up to five times as long as the other parts of the manufacturing process.

We also turn parts like shafts and screws, which we do on a lathe under a microscope or manufacture them ourselves from raw components. We want our screws to be of the same high quality as the other parts of the watch. To achieve a flat finish for each individual screw we apply, by hand, a special tin polish. When we talk about finish we are talking about many things that are barely noticeable by most people. But because we believe that the finish is so important to the watch we take much more time to perfect the finish than many other luxury watch manufacturers.

Our in-house production of wheels and pinions includes polishing the flanks. Partially we buy several raw pieces in addition. We finish all pinions extensively with polish and Glashütte’s cut-in, the arms of the wheels are beveled, matted and gold-plated. The wheels of the gear train of all movements are manufactured in solid gold. The winding wheels are given a shiny, double sun-ray finish.

Since 2006 we produce the specially designed moustache- anchor in gold. Here the goldshmithing and the fine mechanical technology goes hand in hand.

The balance in the Lang & Heyne Design is provided with a mainspring, of course with a breguet overcoil, to achieve a harmonic oscillation.

When all the pieces are manufactured and finished, the sub-assembly of the prototype follows. That is the real challenge for the watchmaker. Now, all the pieces have to mesh together, all the jewels and pivots have to be pressed fit, the wheels have to be adjusted. Some parts may have to be changed or made in a completely new way.

Finally, after all our hard work, we can celebrate the birth of a model: the first tick-tock of the new watch. About eighteen months after we start, after the «groundbreaking» we begin the preparation for the tradeshow presentation.

But first, we have to pay attention to the «face». The eroded hands will be filed in the bench vise and engraved under the microscope. Followed by the grinding, the polish, the blueing and the rivet with the hand collets. The dial made of enamel or silver receives dial feet and finally the movement can be put in the case. The fine alligator strap and the clasp complete the watch and we can feel it the first time on our wrist.

A festival for the eyes, which makes us proud.

LESS IS MORE, EVEN LESS IS EXCLUSIVE...

See our whole collection and find your personal masterpiece.