Do you have an incredible idea, yet seem to have trouble turning that idea into an actual prototype?

If you answered, “yes,” have no fear because this is one of the most common problems across the entire industrial marketplace.

How do you take a seemingly perfect idea in your mind and ultimately bring it to life?

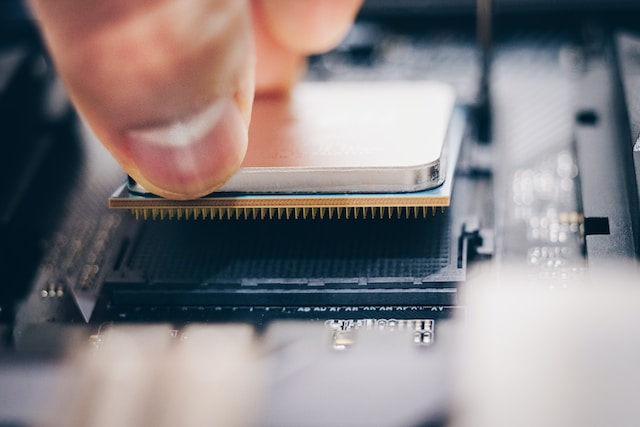

The answer is simple… CNC Manufacturing.

At the moment, raw materials (commodities) and energy product prices are being driven downward due to increased supply, which technically should be good for business, yet doesn’t take into account the uncertainty encompassing industry political leadership and direction.

In fact, uncertainty leads to less demand and more market selloffs.

It’s important to utilize market metrics that are very specific to your industry.

Protomatic, for example, provides raw data for one of the best indexes for metalworking industries, the Manufacturing Index compiled by Gardner Business.

This index is specific to metalworking industries and is helpful in understanding business direction on a national level.

Recently, Protomatic honed in on two business directions, classified as reactionary and steadfast.

Reactionary businesses include those found in the energy and energy development segment, which now are in survival mode due to the price of crude oil. As a result, these businesses have transitioned from a lucrative market to a fiercely competitive market overnight.

On the other hand, steadfast businesses can keep a firm business approach toward future goals, even in the midst of uncertain times.

Manufacturing-based companies are continually able to regroup, adjust inventory, accelerate product development, and even work on smaller ROI projects while the political and economic markets are in turmoil.

Making the most of slow times is a positive feature of a slow down, as it allows people and companies to innovate.

Work on that unattended project again, improve an ongoing process, or…

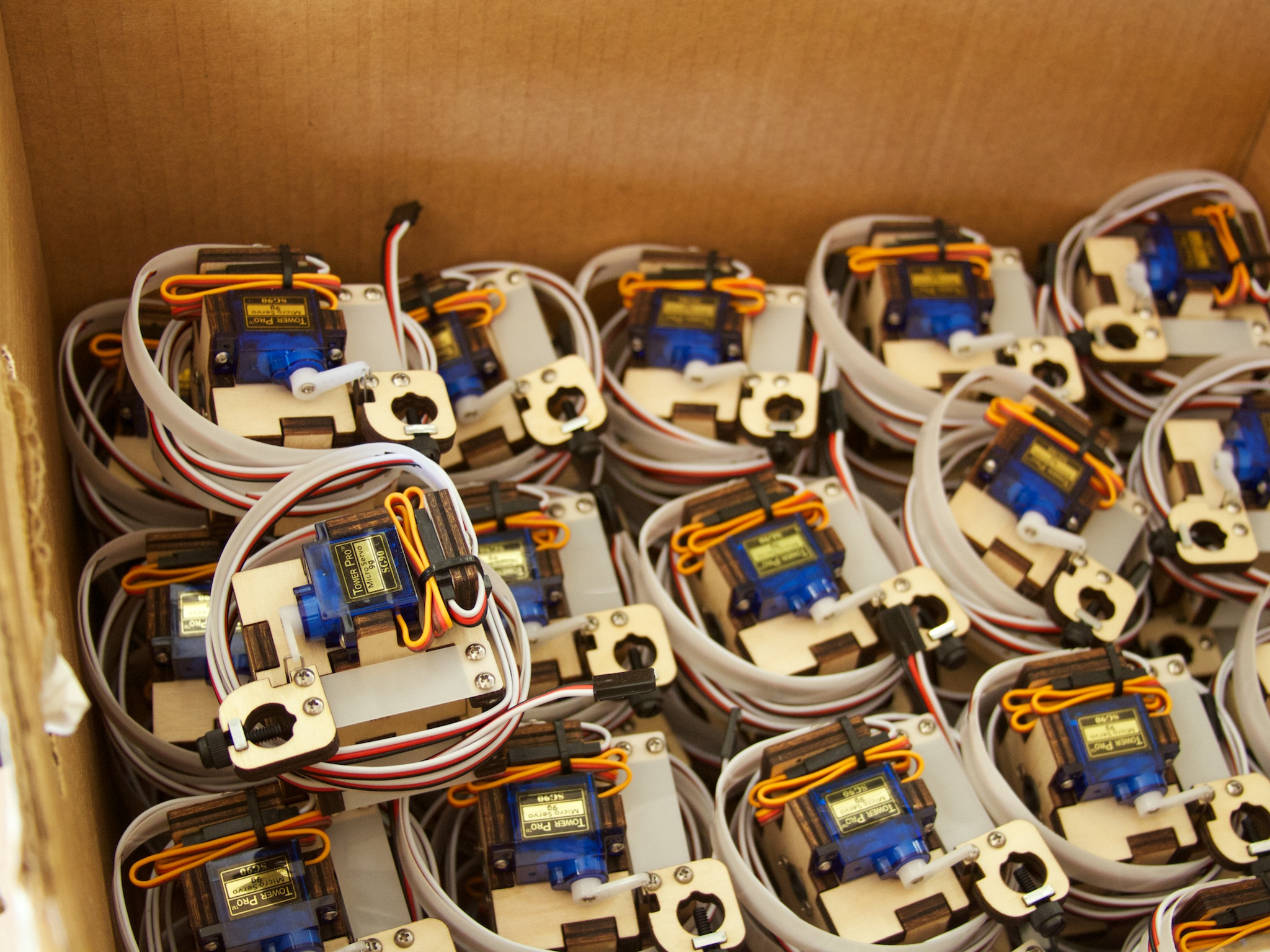

Create a new product or prototype.

During this time of slow down, focus on the incremental ROI projects that may not have been getting sufficient attention when everyone was so busy. This can lead to real, measurable improvements in areas such as product innovation, quality, and manufacturing efficiency, which will improve your company’s bottom line.

What is Protomatic doing?

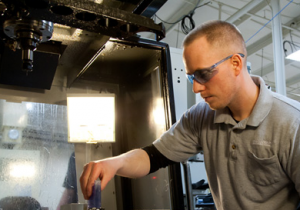

The neat thing is that the CNC manufacturing industry is highly flexible and agile, and able to convert and redirect our efforts for the success of our customers. Some of the programs in place at Protomatic for 2016 include working on special projects to gain efficiency, 5S programs to improve organization, and implementing new process-based software. Additionally, we are conducting skills-based training on new equipment with a Gen X and Gen Y focus, and implementing automation plans to reduce costs. These efforts lead us to continue providing Life-Saving Precision in all aspects of our business.

Download Protomatic’s FREE eBook For More Information:

Protomatic is a CNC precision machining shop specializing in prototype and short-run production components for the medical, aerospace, and other technical industries. Because of the critical nature of the parts they design and manufacture, the emphasis is always on Life-Saving Precision.