The US Army Corps of Engineers (USACE), a federal agency under the Department of Defense, has developed and patented a concrete composition that enables 3D printing for building components demanding high structural strength.

Using this composition, the USACE can potentially accelerate construction of buildings for a wider variety of military and civilian operations.

Cement & concrete 3D printing

Cement 3D printing has become the subject of several academic and commercial projects. Research from the Technical University of Munich (TUM) investigated the value of various methods of 3D printing cement while 3D construction projects from APIS COR, and IAAC are demonstrating the potential.

During the development of the concrete composition, USACE research came to the conclusion that cement-based materials are less likely to clog machinery, whereas concrete, due the mix of concrete and aggregate – i.e sand, gravel, crushed stone etc., has a higher tendency to clog machinery.

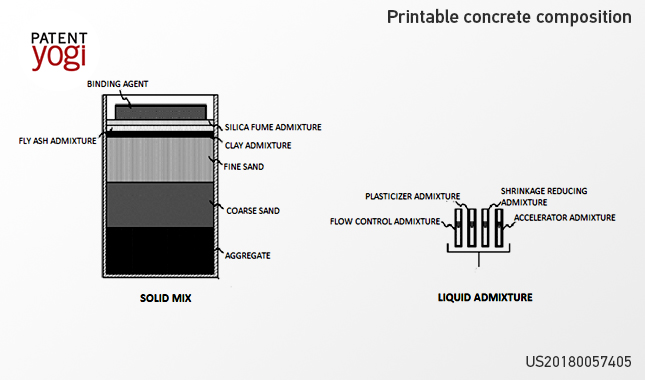

To remedy the limitations of concrete 3D printing, USACE created a concrete composition from solid mix, liquid admixture, and water.

The solid mix, which comprises of sand, clay, fly ash (fine particles of coal), silica fume (a byproduct of silicon metal alloys) and a binding agent, provides an increased flow-ability and a diminished set-time for printable concrete composition.

Additionally, the liquid admixture, an amalgamation of fluids added to concrete during mixing in small doses, contains properties that improve the flow and pumping of printable concrete composition at high pressures. This includes a plasticizer, additives that increase the plasticity or decrease material, and chemical admixtures that reduces cracking and shrinkage of the composition upon drying.

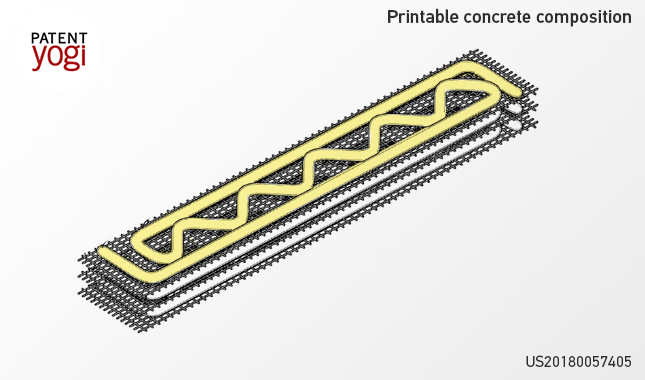

As a result of this new concrete composition, military engineers can print structures that do not need composite modification; moreover, this composite can be used between mesh layers to further strengthen or stabilize a printed structure, ultimately reinforcing the integrity of a building.

3D printed housing for soldiers

The US Armed Forces have identified the growing uses of additive manufacturing within construction. Last year, the Construction Engineering Research Laboratory (CERL) successfully constructed its first 3D printed barracks hut in Champaign, Illinois.

Typically made from plywood, the semi-permanent cement B-Hut demonstrates the potential for 3D printed cement barriers, culverts, and obstacles that can house soldiers, improve military transportation, and increase training facilities.

“ACES provides a capability to print custom designed expeditionary structures on-demand, in the field, using locally available materials,” said Dr. Michael Case, manager of the CERL’s Automated Construction of Expeditionary Structures (ACES) project.

Keep up with the latest news in additive manufacturing and construction by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows wall structure produced using concrete 3D printing. Photo via TU/e.