Article courtesy Underhood Service.

Q: When should an oxygen sensor be replaced?

A: Only when it is necessary. Most late-model vehicles do not have a recommended replacement interval for oxygen sensors, though some oxygen sensor manufacturers do say that replacing O2 sensors at high mileage is a good way to ensure peak performance and fuel economy.

Like other engine sensors, there’s no need to replace an O2 sensor as long as it is working properly and accurately reading the oxygen content of the exhaust. It is generally assumed that as long as the Check Engine light is off and there are no O2 sensor codes, the O2 sensors are probably fine. But this assumption may not be correct in the case of a sensor that is biased rich or lean, or that has become sluggish and is slow to respond to changes in the air/fuel mixture. Such problems may not be bad enough to set a code, but they could have a detrimental effect on engine performance, fuel economy and emissions. If an O2 sensor is not reading properly or is borderline, it should be replaced regardless of its age or mileage.

Aging upstream O2 sensors that have become sluggish or contaminated will typically make the air/fuel mixture run rich. The engine computer (PCM) uses input from the O2 sensors to adjust the air/fuel mixture. If the voltage output from the sensor is low (indicating a false lean condition), the PCM will make the fuel mixture richer to compensate. This increases fuel consumption and emissions.

A bad O2 sensor can also prevent some of the OBD II readiness monitors from completing their self checks. This, in turn, can cause a vehicle to be rejected if it has to take a plug-in OBD II emissions test.

Q: At what point does O2 sensor performance start to decline?

A: It’s hard to say because a lot depends on the condition of the engine. If a high-mileage engine is using oil due to piston ring, cylinder or valve guide wear, phosphorus from the oil will contaminate the O2 sensors and accelerate the aging process. The same applies to coolant that may be seeping past a leaky head gasket.

As a rule, the service life of oxygen sensors in most 1996 and newer vehicles with OBD II should be 100,000 to 150,000 miles or more — assuming no problems that could cause the O2 sensors to fail prematurely.

Q: The Check Engine light is on and the code is P0171 (System Lean, Bank 1). Does that mean it needs a new oxygen sensor?

A: Probably not. If your oxygen sensor were bad, it usually causes the fuel system to run rich. This would likely set a P0172 rich code, not a lean code. Assuming there are no other codes present (no oxygen sensor or other sensor codes), the fuel system may be running lean for a variety of reasons. One common cause is air or vacuum leaks between the throttle body and the cylinder heads. Leaks at vacuum hose connections, intake manifold gaskets, or the PCV or EGR valves can all allow air into the manifold causing a lean fuel condition. Dirty fuel injectors or low fuel pressure can also cause a lean fuel mixture, as can a dirty mass airflow (MAF) sensor (cleaning it with aerosol electronics cleaner can often resolve that problem).

Air or vacuum leaks in the engine, as well as compression leaks or engine misfires, can fool the O2 sensor into generating a false lean signal when unburned air passes through the engine into the exhaust.

When the O2 sensor detects a higher than normal amount of oxygen, its voltage output drops down to a couple of tenths of a volt. This sends a lean signal to the powertrain control module (PCM), which tries to compensate by adding more fuel to the fuel mixture. Consequently, the engine then runs too rich, wastes fuel and pollutes.

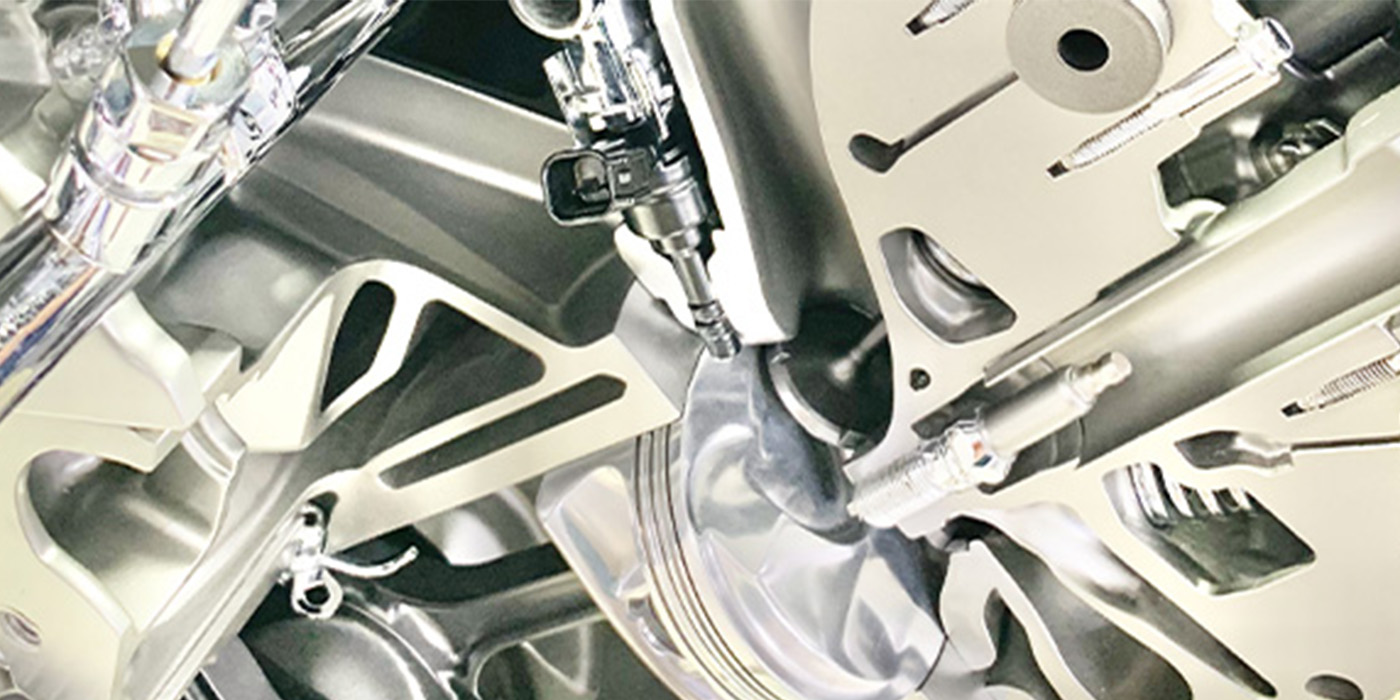

The sensitivity and reaction time of oxygen sensors slows with age, and the zirconium ceramic sensing element inside the tip can become contaminated if the engine is burning oil or develops a coolant leak in the head gasket or one of its cylinders.

O2 sensors must react quickly to changing oxygen levels in the exhaust, otherwise the computer response will be too slow to keep things in balance. A good O2 sensor should switch from a rich-to-lean indication in 20 to 40 milliseconds (that’s 20 to 40 thousandths of a second!), and a lean-to-rich transition in 60 to 80 milliseconds.

Q: My Toyota has something called an Air/Fuel sensor instead of an oxygen sensor. What’s the difference?

A: An Air/Fuel sensor is just a smarter oxygen sensor. An ordinary O2 sensor reads unburned oxygen in the exhaust, and generates either a high or low voltage signal. The signal is high (0.7 to 0.9 volts) when the air/fuel mixture is rich (little O2 in the exhaust), or low (0.1 to 0.3 volts) when the air/fuel mixture is lean (lots of O2 in the exhaust). As such, it works more like a Rich/Lean indicator switch.

An Air/Fuel sensor, by comparison, does not generate a high/low voltage signal. Rather, it generates a current signal that changes in direct proportion to the air/fuel ratio. As such, it can tell the PCM the exact air/fuel mixture, and not just give a rich or lean indication as conventional oxygen sensors do. An air/fuel sensor can also read very lean air/fuel mixtures with a high degree of accuracy, which helps the PCM minimize exhaust emissions.