Cabling Solutions for High-Noise, High-Speed, and Long-Distance Networking

Twisted-pair copper cabling is the perfect solution to a number of applications, but as high-speed signals are required to travel longer distances with higher signal integrity, fiber emerges as the clear winner, even in terms of cost.

When you think about physical networking, what terms pop into your mind? More than likely, you think of things like Ethernet, RJ45, twisted-pair, and CAT5 or CAT6 cabling. These are very common terms that relate to a reliable, tried-and-true medium for networking: copper.

Copper is great – it’s rugged and durable, it’s easy to terminate, and it’s inexpensive. However, copper does have one kryptonite: electromagnetic interference (EMI). EMI can wreak havoc on copper network lines, causing signal degradation and possibly total data loss altogether. How do we protect our networks against the negative effects of EMI? One solution is a change in transmission medium. This is where fiber optics come in.

Fiber optics utilize thin strands of glass fiber and light to transmit data. Since glass is a very poor conductor of electricity, fiber optics make EMI a non-issue. For this reason, fiber is being installed in more and more places, especially in industrial applications involving power transmission and distribution. In addition to EMI immunity, fiber optics also provide benefits in speed and distance, bandwidth, and installation time.

Immunity to Noise

Twisted-pair copper cabling is great, and it’s the perfect solution to a number of applications, but as high-speed signals are required to travel longer distances with higher signal integrity, fiber emerges as the clear winner, even in terms of cost.

Perhaps the biggest problem that fiber optics solves — depending on the industry — is the problem of noise. EMI, a type of electrical noise, is a huge problem in many industrial environments. EMI basically bleeds electricity onto metallic conductors that are in the surrounding area.

If EMI bleeds onto a network communication line, the result can be a weak, garbled signal on the receiving end. Copper twisted-pair cables combat this by wrapping the pairs in layers of foil, braided shielding, and PVC or PUR jacketing. Yet, even with all of this protection, strong EMI can get through and tarnish signals.

Fiber optics eliminate this problem completely. The science is simple; glass is not a good conductor of electricity. This means that fiber can go where copper cannot. Fiber cables can be run in the same cable trays and conduit as power cables. It can be used to run monitoring and diagnostics on power systems. It can even be used as a complete networking solution in power substations, where data communication is crucial to the integrity of our power grid.

When you combine the distance capabilities of fiber with its immunity to EMI, you’re basically left with a silver-bullet solution for power utility companies. Fiber optics enable electric utility data centers to communicate with power substations in the field in real-time. Once a connection is established between these two points, fiber is used to communicate with voltage controllers, sensors, relays, video cameras, and other devices within the substation. This is just one of many examples in which fiber makes a true difference.

Cabling Speed and Distance

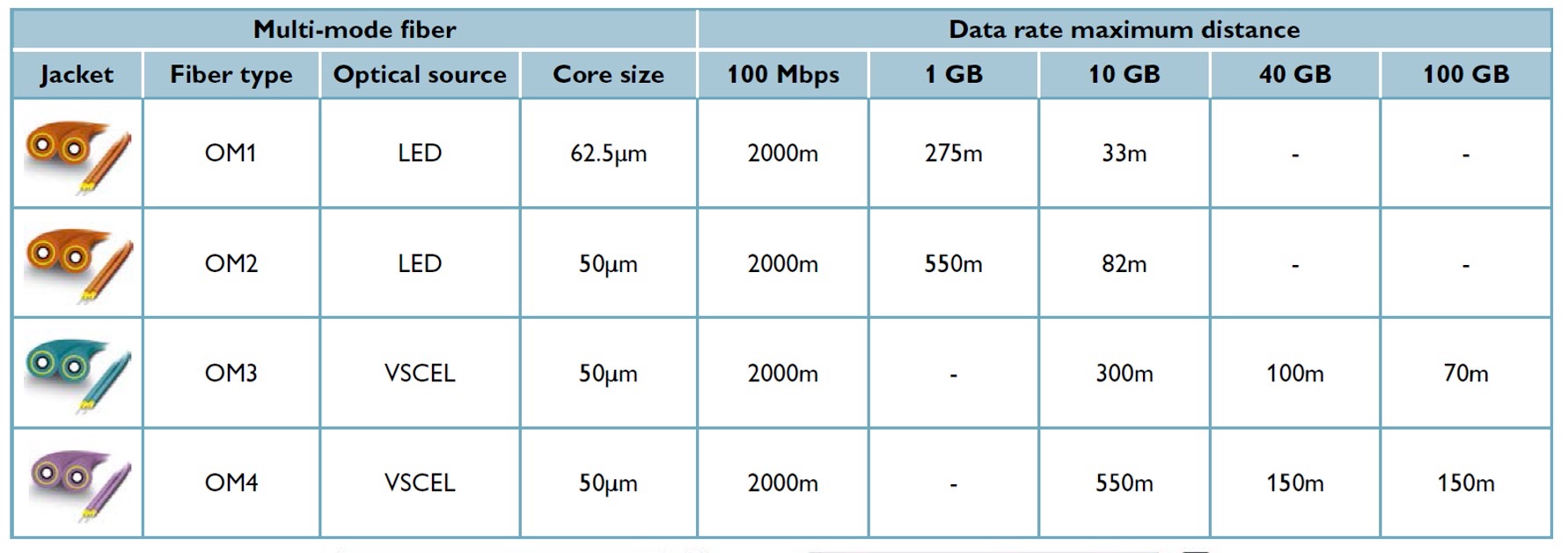

When it comes to network speed, one thing is clear: Faster is better. As time marches on, networking requirements call for faster and faster speeds. Right now, most industrial applications require speeds up to 1Gb/s (CAT5e), but a move to 10Gb/s (CAT6A) is already underway. While copper is perfectly fine for short runs at these speeds, things change when you get outside the plant. Typically, Ethernet categories are only rated for use up to 100 meters or about 0.06 miles. Once you get beyond that point, twisted-pair cabling needs help. This can come in the form of Ethernet repeaters or extenders, but adding these components can quickly get expensive. So, this is another situation in which fiber optics can make a big difference.

Fiber optic cables offer high transmission speeds, optimum attenuation properties, and high resistance to electromagnetic interference, and provide 1,000 times the bandwidth that copper does, making it the transmission medium of the future.

Single-mode fiber can carry a 10Gb/s signal up to 10 kilometers. That’s 100 times farther than copper twisted-pair cabling can take that same signal. While it’s true that fiber is more expensive than copper when compared directly to each other, getting a twisted-pair cable run to 10 kilometers would require the use of 100 Ethernet repeaters. When you add in this additional cost, it’s easy to see that fiber optics is the more frugal choice. It’s no wonder why fiber to the home (FTTH) is replacing traditional copper cabling in more and more places.

Bandwidth

While we’re comparing fiber optics and copper twisted-pair cabling, we should also talk about bandwidth. Fiber provides over 1,000 times the bandwidth that copper does. Since fiber allows data to travel at the speed of light, measured bandwidth clocks in at about 60 Tb/s (i.e., 60,000 Gb/s). Compare this to the 10 Gb/s that copper can accomplish, and you can see which transmission medium is the future of networking.

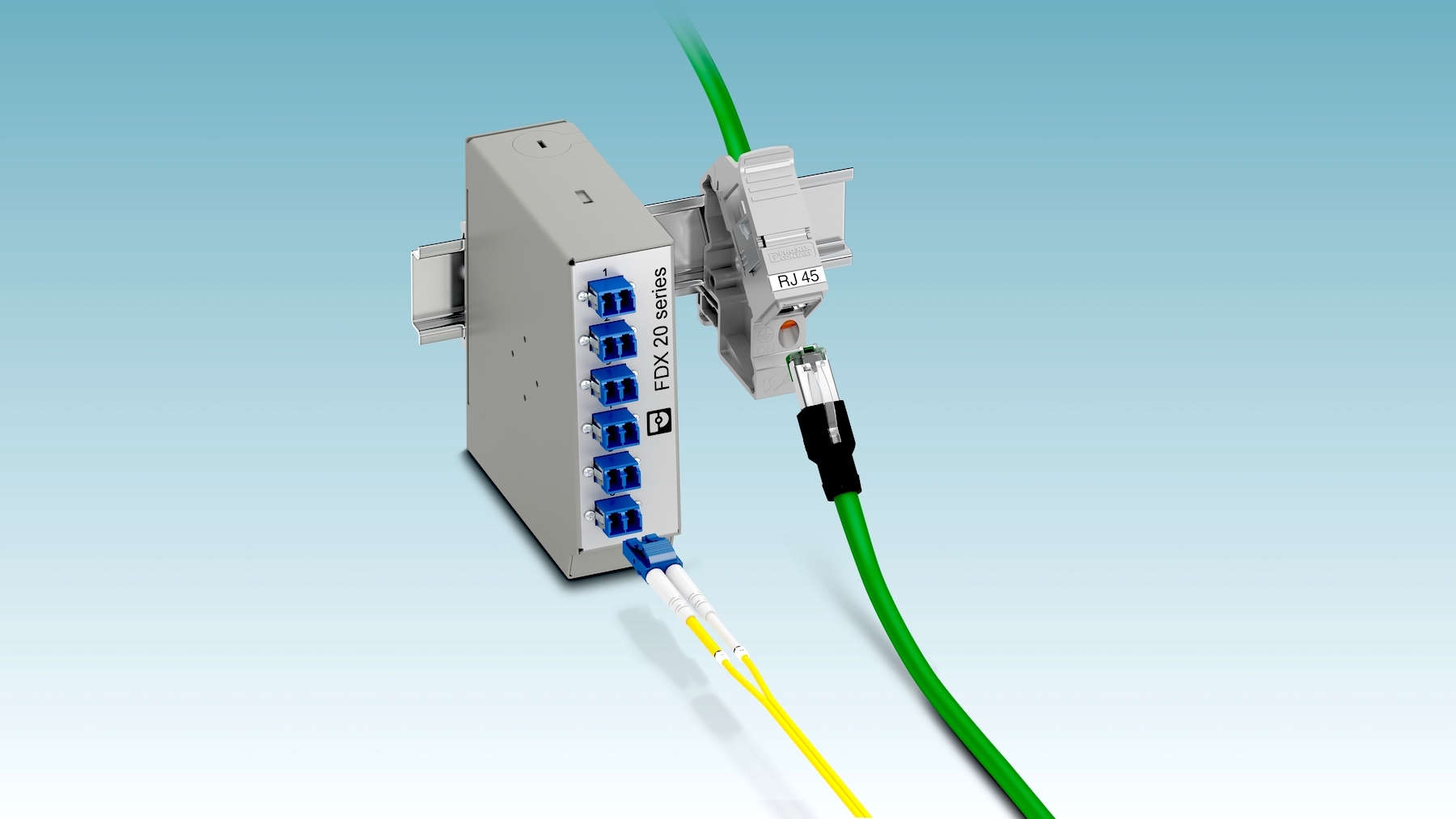

Phoenix Contact’s FDX 20 splice boxes ensure reliable data transmission in real time. With their compact, uniform design, the splice boxes ensure ample interior space for secure connection of fiber optic cable.

Installation Time

In industries that require a lot of connectors, it’s important to pick products that save time and are easy to work with. Fiber-optic cabling is much smaller than copper cabling, which saves space not only inside facilities but in conduit as well. Long runs of underground conduit connect buildings together, and some of these runs can stretch for miles. It’s important to be able to fit all necessary cabling in these stretches of conduit, as well as to be able to pull the cabling through.

Fiber cabling weighs about four pounds per 1,000 feet, while copper weighs in at around 39 pounds per 1,000 feet, and because it’s lightweight, it’s easier to pull fiber through long pieces of conduit. When you pair this fact with the expectation for fiber to last 30 to 50 years, versus much shorter life expectancies for copper, it only reinforces the argument for investment in fiber optic cable.

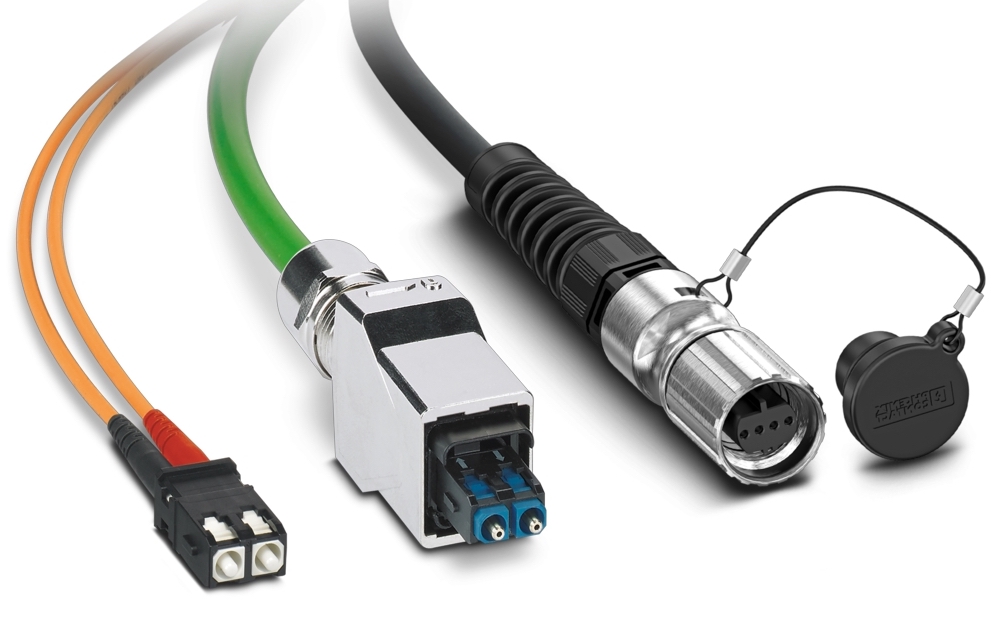

Once inside a building, fiber can be terminated using a variety of methods, including connectors, fusion-spliced to fiber optic pigtails, and even connected through plug-and-play systems such as multi-fiber push-on (MPO) connectors. Phoenix Contact offers a range of cable assembly termination products that serve fiber-specific goals.

Once inside a building, fiber can be terminated using a variety of methods. Individual strands can be terminated with connectors, fusion-spliced to fiber optic pigtails, and even connected through plug-and-play systems such as MPO connectors. Due to the physical properties of fiber optics, signal loss or degradation is very minimal when terminating. The same can be said about copper but not to the degree of a fiber splice/termination.

There’s no doubt that twisted-pair cabling is great, or that it’s the perfect solution for many applications. However, when we begin to push the limits of copper regarding distance, performance, and shielding, it’s hard to argue against the switch to fiber optic cabling. Wherever an impervious networking solution is needed, trust fiber optic cable to go the distance.