Meet the People (and Robots) Who Pack Your Online Orders

A dispatch from a massive distribution center

It was blisteringly hot outside the downtown Chicago office when my colleagues started swapping PowerPoints about holiday marketing plans. My summer internship at a major online retailer was in its last week, and in addition to several abrupt goodbyes, the majority of hallway chatter involved speculation around online sales estimates for the upcoming holiday season, and what new devices consumers would be using to place their orders.

This end-of-year spending frenzy is endemic to American culture, but this was my first experience from the other side of the transaction—which begins months before the actual season. Earlier that summer, the interns were taken on an off-site field trip to one of the company’s distribution centers (DCs) in a rural part of Wisconsin, just off Interstate 94. The prelude to the consumer's holiday shopping season is a massive, pre-holiday-rush mobilization that occurs across a network of 22 warehouses in outer-suburban areas across the country.

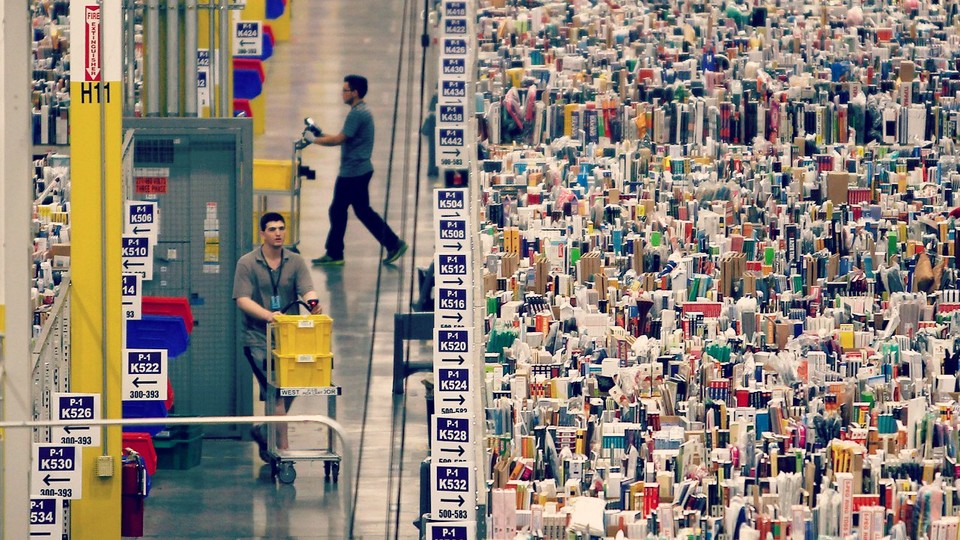

DCs are the physical space where retailers grapple with the enormous task of receiving tens of thousands of products in large industrial-sized boxes, unpacking and sorting those items across a vast space the size of several football fields, and lastly re-packaging each item into a smaller box that can be delivered to retail stores and customers’ front door steps. It is a task that requires almost unimaginable amounts of coordination that's largely unacknowledged by the consumers who want their items to arrive fast (and free).

Inside the cavernous warehouse, countless items were being shuttled through a nest of aluminum chutes and slides and carousels, and temporarily housed in hundreds of shelving units and bins. It was unnervingly quiet: The only background noises were a dim machine hum whose source was imperceptible, and the occasional blip or bleep from forklifts and carrier vehicles moving about the space. The floor manager barely had to raise his voice to be heard.

“It’s important to remember,” the manager said as he guided us around the space. “This is not a warehouse. It is a distribution center. Nothing stays here longer than 48 hours.”

The first worker we met was a middle-aged woman, let's call her Susan, who was assigned to the “picker” station where shipping containers with the appropriate product items for each customer order are filled. She stood in front of a tall shelving unit and wore padded braces around both her arms and knees. Dozens of bins on each shelf took turns lighting up red and Susan’s hands promptly followed, retrieving items and dropping them into a larger container on the conveyor belt behind her.

One LED screen instructed Susan on how many items to retrieve from each bin. A second LED screen displayed a timer which kept track of her fill rate, basically the only productivity factor on which pickers are evaluated. Susan was on pace to “pick” about 120 items an hour (just below the cited industry standards ranging from to “200 to 400 items an hour”). The job operates on a kind of arcade game logic: a plethora of blinking lights and rapid directional movements, all playing toward the ultimate goal of marginally more dexterous speed and a new high score.

Susan and her co-workers appeared in good spirits as the manager introduced them by name and told us how long they had been working at the company. About half of the workers had a mental or physical disability, a result of the company’s “inclusion” program which mirrored similar efforts at other major retailers. In a news segment about a DC in South Carolina, one disabled worker said hers was “the coolest job in the world.”

These programs are viewed as leading examples of combined corporate and social success, but that success may be short-sighted. Pickers and low-skill jobs of the sort represent a pain point for DCs and the e-commerce executives who are managing their evolution. The jobs appear simple (one Amazon executive referred to the workers as like “robots in human form”), but the tasks are difficult to automate at scale: “Because products vary so much in size and shape and because of the way they sit on shelves, robotic manipulators still can’t beat real arms and hands,” explains Erico Guizo on Spectrum, the blog for the Institute of Electrical and Electronic Engineers (IEEE).

Unlike Susan and her co-workers, who were salaried and long-time employees of the company, a growing number of “pickers” at DCs across the country are hired through staffing agencies and classified as “non-permanent” or “temporary.” This means no health care coverage or benefits, pay that's usually barely above the minimum wage, and employment that can be voided at a whim when the workers are no longer needed.

This tenuous labor arrangement is partly the result of an honest fluctuation in the demand for these jobs: The biggest influx of DC workers occurs just before the holiday season, when online retailers conduct a majority of their annual business. But like retail jobs, the arrangement is also an acknowledgement of the underlying economic reality: The jobs are utterly low-skill, and there exists a large supply of unemployed Americans willing to do the work.

“In a way, because low-wage jobs are so cheap, we haven’t seen as much automation as you could,” Joseph Foudy, a professor of economics at NYU’s Stern School of Business, told me.

In addition to low pay, these workers are often subjected to unreasonably grueling labor conditions, precisely because they are temporary, cheap, and easily replaceable. Journalist Mac McClelland described her experience working at an amalgamated warehouse in rural Mississippi where she made rote physical movements thousands of times a day for only “60 dollars-a-day after taxes,” alongside people coping with labor-induced ailments (such as arthritis and tendonitis) while lacking any health care coverage, and being told that “taking 800mg of Advil a day” is just a fact of life.

Facility conditions at DCs are also often neglected or managed on an obsessively low-cost basis. It took an investigation by The Morning Call into one of Amazon’s Pennsylvania warehouses—which found dangerously hot summertime conditions and dizzying work paces—for the company to finally fork over $52 million to install proper ventilation. Reporting on an Amazon “fulfillment center” in the small English town of Rugeley (a former coal town), Financial Times writer Sarah O’ Connor found a disillusioned community jaded with the promise of new jobs, but had complaints about a work environment that resembled “being in a slave camp.”

Despite the controversial nature of these jobs, many politicians—still fighting back from recessionary employment levels—have touted their arrival. In July 2013, President Obama gave a speech from the floor of an Amazon “fulfillment center” in Tennessee where he praised the company for “investing in American workers and creating good, high-wage jobs.” Politicians in California have welcomed the surge of investment into new DCs across Moreno Valley and Inland Empire, in an effort to transform the region into “the nation’s largest hub of distribution warehouses.”

“We know we face challenges, and [DCs] bring in jobs and pump up the economy right away,” Moreno Valley’s director of economic development told The New York Times. A local economist quoted in the story also noted that it's “the only industry adding thousands of jobs.”

But are DC workers really getting what politicians are calling "high-wage jobs"? The workers Obama referenced in his speech—Amazon’s “fulfillment center associates”—receive on average $11-13 an hour, or around $25,000 a year. A UC Riverside Policy Matters report found that 41 percent of blue-collar DC workers across the Inland Empire region are paid less than $10.50 per hour. The fact these new jobs pay so little, and are often staffed through "temporary" arrangements, means that any supposed economic “gains” brought about by their arrival are precarious.

“This [DCs] could create short-term jobs, but I see no sort of long-term or even medium-term benefit or clustering effect for the local economy out of this,” says Foudy.

DCs are hugely important to online retailers, who are competing in a lucrative market that's expected to grow over 10 percent annually through 2018. It's an industry where “speed of delivery” represents a crucial competitive advantage. Amazon is on track to build a dozen new DCs a year in the U.S. alone and recently spent close to $1 billion acquiring Kiva Systems, a company whose “mobile” robot technology automates the movement of shelving units and increases worker “fill rates” to over 600 items per hour—that's nearly 2-3 times faster than a human worker. More than 80 percent of large distribution centers throughout North America and Europe have committed to expanding automation spending through 2015.

“In the long run you actually hope the job is automated, but you have to worry about the transition of the economy and the production of the jobs to replace them,” says Foudy. “We often forget that in the long run of history, we have already eliminated enormous numbers of unpleasant jobs in industries like agriculture and construction.”

Some retailers who enjoy the benefit of relatively uniform product lines have already opened fully automated DCs. Stock “picking” at Adidas’ latest DC facility in Germany is done only by machines, and companies such as Zappos.com and Diapers.com have similarly automated warehouses. In this context, the new challenge and job potential for humans is to design, install, and manage these new automated environments.

IEEE Spectrum's Guizo interviewed Kiva’s founders about the company’s early vision for “huge warehouses with thousands of robots,” operating perfectly in sync in a way that was “beautiful…like a dance.” They recalled a particularly ambitious engineering intern from the Massachusetts Institute of Technology who memorably choreographed “two dozen robots to dance to the score of Tchaikovsky’s The Nutcracker.”

The aura surrounding DCs and their extraordinarily complex logistics could indeed resemble something magical, like a beautiful robotic ballet, or the fantastical world of cartoon creatures that Coca-Cola invented to give customers a prettier image of what happens inside of vending machines. This is a strategy that Amazon seems poised to pursue, as its latest PR blitz centered around the fleet of 10,000 Kiva robots powering its DCs and speeding up delivery times.

Currently, DCs remain tarnished by too many stories of human abuse and neglect. It is a violation that will only grow in the near-term as retailers expand their distribution arms and hire loads of temporary workers to fill DCs around the clock. Although a roomful of dancing robots may seem a bit dystopian, it beats the present-day reality, and the tens of thousands of beleaguered workers who are probably counting down the days until this holiday season is over.