Impact of Hook & Loop Directionality on Product Performance

A common misconception is that ANY hook and ANY loop configuration will work for a particular product or device. The fact of the matter is that deciding what hook and loop configuration to best fit into a product is much more complex. Directionality plays a major role in fastener performance and ultimately final product performance.

BASIC HOOK AND LOOP DIRECTIONS

Basic hook and loop manufacturing starts with making roll goods at varying widths. The direction that the product is spooled is noted as the Machine Direction (MD). The opposing direction, or width direction, is noted as the Cross Direction (CD). In most cases, both hook products and loop products are strongest in the Machine Direction (MD).

FOUR MAJOR ATTACHMENT METHODS

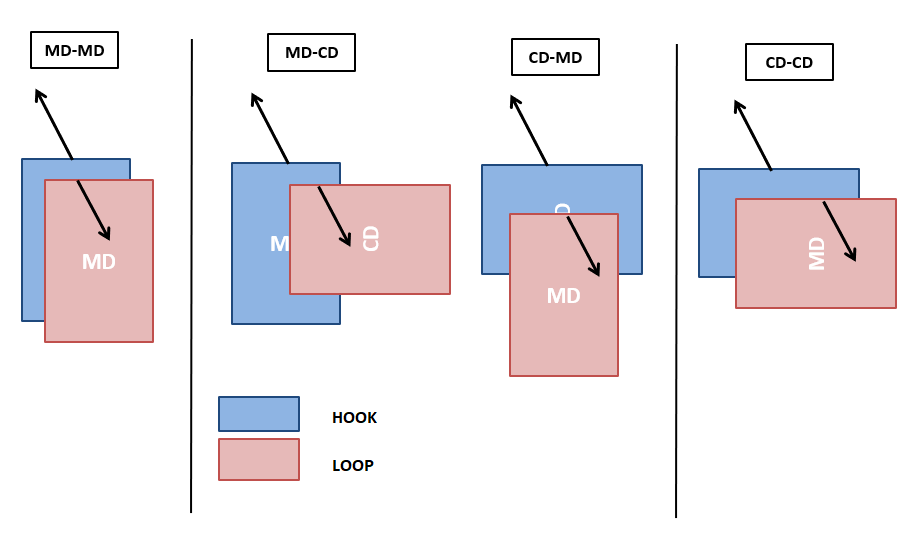

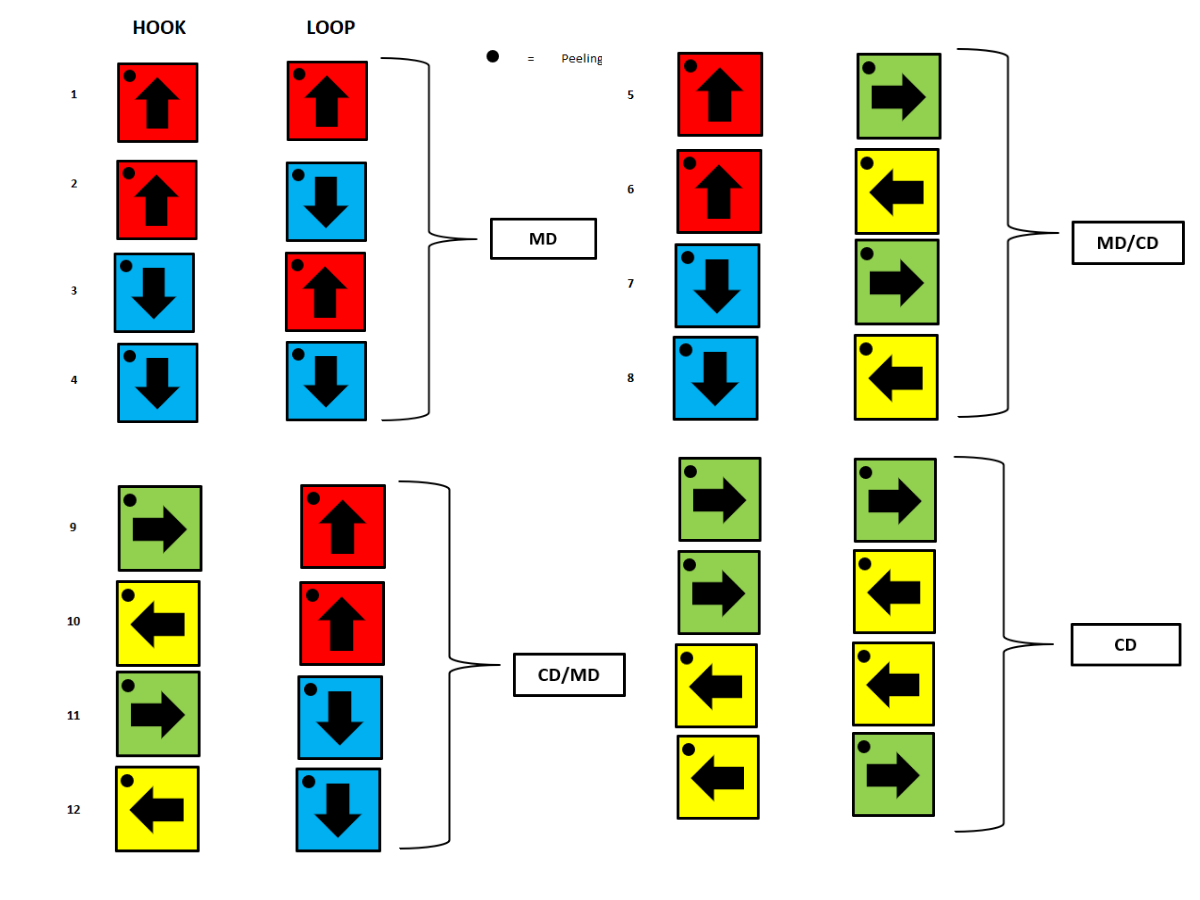

When deciding what hook and loop configuration to best fit into a product, you must first understand that there are four major engagement methods. The four configurations are:

1) Machine Direction (MD) -to- Machine Direction (MD)

2) Cross Direction (CD) -to- Cross Direction (CD)

3) Machine Direction (MD) -to- Cross Direction (CD)

4) Cross Direction (CD) -to- Machine Direction (MD)

Figure 2 below better visually represents the four different means of attachment.

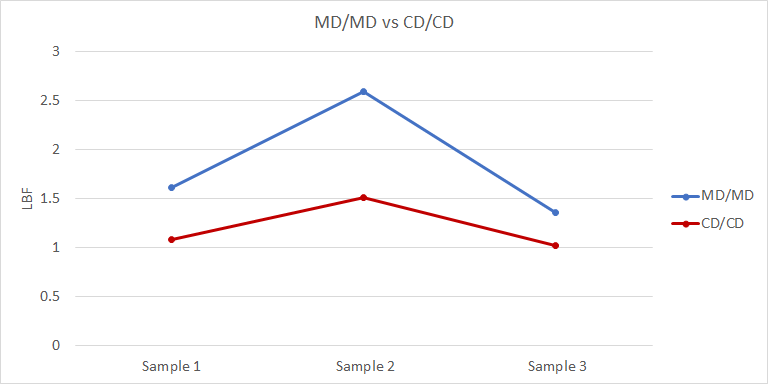

It’s important to understand that for each of the different attachment methods, there are different strengths associated. One of the biggest differences in strength can be seen in the MD-to-MD vs. the CD-to-CD. Graph 1 below explains the major strength drop between the two. In some instances, you can expect to see a 40-50% drop in strength.

SUB-DIRECTIONS

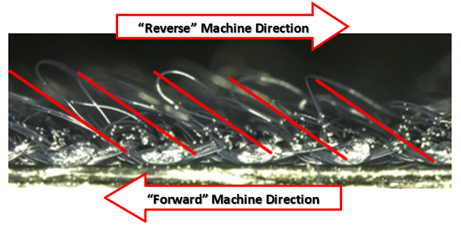

For each of the four major directions, there are an additional four sub-directions. This is most easily explained as “reverse” direction. For example, for MD-to-MD, you can potentially have “forward” MD and “reverse” MD. This is much more noticeable in loop products because loop fibers have a higher likelihood to “lean” to one side. Figure 3 below explains this in more detail. This can cause vastly different strength values.

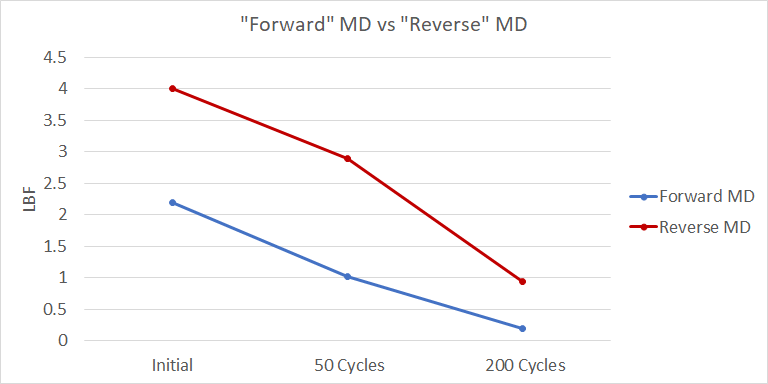

Some of the largest fluctuations in strength can be found in the MD-to-MD attachment method. In one particular YKK test, the loop was examined in both “forward” MD and “reverse” MD. Graph 2 below displays the findings of the YKK study. The results of this study indicate that, by simply installing loop in the opposite direction, you can potentially decrease the performance by 30-50%.

Below is a list of every possible direction and attachment method.

There are a total of 16 different attachment methods for hook and loop, all of which can greatly impact the hook to loop strength. When using hook and loop in an application, it is not enough to simply look at the product itself. You must also understand that directionality plays a major role in fastener performance and ultimately final product performance.

Please contact YKK for further guidance on how to properly attach YKK® hook and loop products.

This article was written by Mike Fleming, R&D Advanced Engineer – Textile & Plastic Products, YKK (U.S.A.) Inc.